100W vs. 400W Solar Module | Which is the Better Choice for You

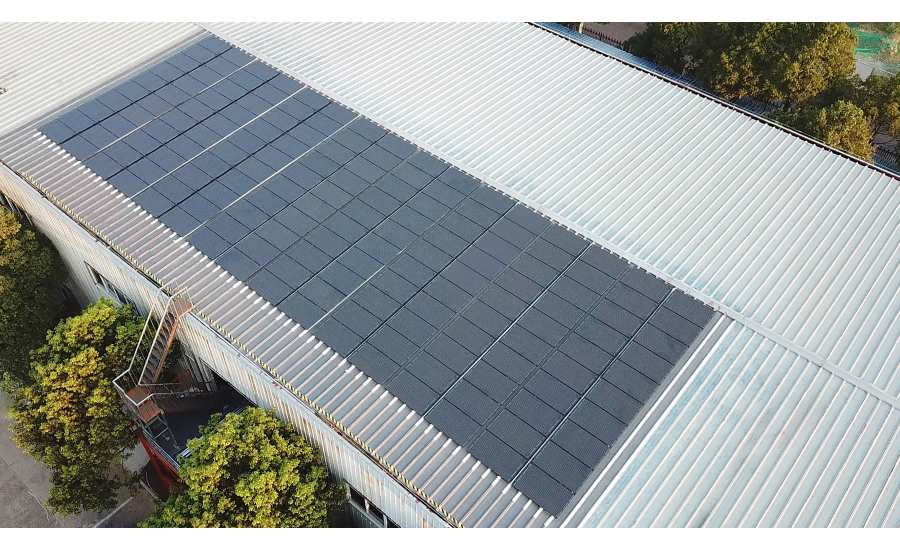

The choice hinges on your available space and power needs; a 100W panel is portable for RV/camping use (1㎡), while a 400W panel (2㎡) is far more efficient for home grid-tie systems, requiring fewer units and less wiring to achieve significant energy output.

Power Output

A 100W module has a maximum hourly energy generation of approximately 0.1 kWh, while a 400W module can reach 0.4 kWh.

This difference directly determines the divergence in application scenarios: 100W modules are typically used for charging 12V cell systems or running small devices; 400W modules are designed to power residential grid-tied systems.

Their higher power density is achieved by integrating more efficient cells onto a standard size of about 1.6-1.8 square meters.

Rated Power

The rated power on a solar module, such as 100W or 400W, is a result obtained under strictly controlled laboratory conditions.

This environment is called "Standard Test Conditions" (STC), which acts like a fair ruler, allowing all modules to be compared on a level playing field.

STC specifically includes three precisely set parameters:

l Irradiance: Must reach 1000 watts per square meter. This simulates the energy intensity of sunlight shining perpendicularly onto the Earth's surface at noon on a clear day.

l Cell Temperature: Constant at 25°C. It refers to the temperature of the solar cell itself, not the ambient air temperature. Under sunlight, the actual temperature of the cell is usually 20-30°C higher than the ambient temperature.

l Air Mass: Defined as AM 1.5. This indicates the path length of sunlight through the atmosphere and is a standardized solar spectrum model.

Why Rated Power is Almost Never Achieved in Actual Use

After outdoor installation, a module's output power fluctuates continuously and is below the rated value most of the time. This is mainly caused by the following unavoidable real-world factors:

1. Light intensity is never as stable as in the lab

During the day, only the hours around noon may have light intensity close to 1000 W/m².

In the early morning, evening, on cloudy or overcast days, irradiance can drop significantly to 300-600 W/m², at which point the module's actual output power decreases proportionally.

For example, a 400W module at an irradiance of 500 W/m² will have an instantaneous output power of only about 200W.

1. The effect of temperature: Why power generation decreases when it's too hot

Temperature is one of the main factors affecting output power. Solar cells have a temperature coefficient, typically -0.3% / C to -0.4% / C.

When the cell temperature exceeds the STC baseline of 25°C, its output power decreases.

For example:

l A module with a rated power of 400W and a temperature coefficient of -0.35%/°C.

l On a sunny day with an air temperature of 30°C, the cell's actual operating temperature under sunlight might reach around 55°C.

l Temperature difference: 55°C - 25°C = 30°C.

l Power loss: 30°C × 0.35% = 10.5%.

The module's actual output power at this time is approximately: 400W × (1 - 10.5%) = 358W.

2. Power loss due to packaging and light-induced degradation

After manufacture, a module's power experiences an initial slight drop, called "initial light-induced degradation."

In the first year of operation, power may drop by 1-2%, after which there is a slower annual degradation rate (about 0.5%).

Therefore, manufacturers usually provide a power warranty, for example, "no more than 2% degradation in the first year, and no more than 0.5% annual degradation thereafter."

After 25 years, the module's output power can still remain above 85% of the initial rated power.

Do modules with different technologies have the same power degradation?

Different cell technologies have significant differences in their power degradation characteristics:

Technology Type | First-Year Degradation Rate | Linear Annual Degradation Rate | Power Retention at Year 25 (approx.) |

Mono PERC (Mainstream) | 1-2% | 0.45-0.55% | ≥85% |

N-type TOPCon | 0.5-1% | 0.4% | ≥87% |

Thin-Film (e.g., CdTe) | 1-3% | 0.3-0.5% | ≥85% |

As can be seen from the table above, more efficient N-type technologies (like TOPCon) perform better in resisting degradation, maintaining higher actual output power throughout their lifecycle.

How Rated Power Affects Your System Design

Choosing modules with different rated powers directly affects the configuration of the entire PV system.

l For off-grid or small systems (e.g., using 100W modules): You need to accurately calculate the total daily electricity demand (in kWh), then, based on the local peak sun hours, determine how many modules are needed. For example, to provide 2.4 kWh per day for a small cabin, if the local average daily effective sunlight is 4 hours, then (2.4 kWh / 4h) = 0.6 kW, i.e., 6 x 100W modules are needed.

l For grid-tied residential systems (e.g., using 400W modules): The design primarily considers available roof area and budget. Total system power (kW) = Number of modules × Single module power (kW). The inverter's rated power should be slightly less than the total module power because the actual output rarely reaches the theoretical peak. For example, 20 x 400W modules (total power 8kW) are usually paired with a 7.6kW inverter.

Power Density

What exactly is power density?

Power density measures how much sunlight a solar module can convert into electricity per unit area.

This metric directly answers a practical question: why do modern new modules generate far more electricity on the same-sized roof than older products from a few years ago.

The calculation is simple: divide the module's peak power (Watts) by its surface area (square meters).

For example, a module with a power of 400 watts and an area of 1.94 square meters has a power density of about 206 W/m².

If another module of the same area has its power increased to 450 watts, its power density increases to 232 W/m².

The increase in power density allows for the deployment of larger generation systems in limited installation spaces.

For ordinary households with limited roof space, this directly determines how much electricity can be self-consumed annually and how much the electricity bill can be reduced.

How technological upgrades step by step increase power density

The increase in power density is not a breakthrough of a single technology, but the cumulative result of the continuous optimization of a series of engineering technologies.

Cell efficiency is the foundation

The most fundamental progress comes from the photoelectric conversion efficiency of the silicon-based cell itself.

From the traditional multi-crystalline Al-BSF technology years ago (efficiency about 17-18%), to the mainstream mono PERC technology (efficiency about 22-23%), to the latest N-type technologies such as TOPCon (efficiency about 24-25%) and HJT (efficiency about 25-26%), the same cell area can generate more electricity.

Advancements in module technology free up space

Beyond the improvement in cell efficiency, improvements in module packaging technology are equally critical:

· Half-cut cell design: Cutting standard cells in half halves the internal current, reduces resistive losses, and actually increases output power by about 2-3%. Meanwhile, the small gaps between the smaller cells increase the light-receiving area.

· Multi-busbar (MBB) technology: The number of conductive lines on the cell surface has increased from 2-3 in the early days to 12-16 now. Thinner, denser busbars reduce shading area and enhance current collection capability.

· Busbar-less and micro-busbar technology: Further replacing flat ribbons with finer round wires, resulting in even less shading; leading manufacturers have achieved over 20 fine busbars.

· Shingled or seamless welding technology: Eliminates the overlapping gaps after traditional cell welding, maximizing the use of the module's light-receiving surface.

The superposition of these technologies allows a new generation of modules to output 30-50 watts more power than older products, while having almost the same external dimensions.

Density comparison of modules of different power levels

The table below visually shows the differences in physical specifications and power density of modules of different power levels, from portable to mainstream residential.

Module Type | Typical Power (W) | Common Size (mm) | Estimated Area (m²) | Weight (kg) | Power Density (W/m²) |

Flexible Portable Module | 100 | 1200 x 540 | 0.65 | 5-7 | ~154 |

Small Rigid Module | 200 | 1480 x 670 | 0.99 | 12-14 | ~202 |

Mainstream Residential Module | 400 | 1722 x 1134 | 1.95 | 21-23 | ~205 |

High-Efficiency Commercial Module | 450 | 1762 x 1134 | 2.00 | 22-24 | ~225 |

Latest N-type Module | 550 | 1779 x 1134 | 2.02 | 25-27 | ~272 |

As the data shows, the higher the power of the module, the higher its power density usually is. In particular, the latest 550W+ modules, by adopting efficient cell technologies like N-type TOPCon, have achieved a significant leap in power density.

The practical impact of high power density on installation and cost

The benefits of high power density are reflected in multiple aspects of system design.

Saves installation space

Assuming a household needs to install a 6-kilowatt system:

l Using 400W modules with a power density of 205 W/m² requires 15 pieces, with a total area of about 29.3 square meters.

l Using 450W modules with a power density of 225 W/m² requires only 14 pieces, with a total area of about 28 square meters.

l For homes with irregularly shaped or space-constrained roofs, these saved 1.3 square meters may determine whether the system can be installed.

Reduces Balance of System costs

Balance of System includes mounting structures, cables, and labor, etc. Reducing the number of modules directly leads to:

· Less mounting material: The rails, clamps, etc., required to install 14 modules are typically less than those needed for 15 modules.

· Reduced installation time: Moving, positioning, and fixing each module takes time.

· Simplified wiring: Fewer modules mean fewer internal connection cables and connectors, not only saving cable costs but also reducing the risk of system problems caused by connection point failures.

System-Level Impact

How the number of modules changes the system structure

When you choose between 100W and 400W modules, the most immediate difference is the number of modules required. For a target system power of 4 kW:

l Using 100W modules requires 40 pieces.

l Using 400W modules requires only 10 pieces.

This huge difference in the number of modules directly changes the physical layout and electrical connection method of the system.

40 modules need to cover a larger roof area and require a more complex wiring scheme to connect them.

In contrast, an array of 10 modules is more compact, with clearer and simpler wiring paths.

Complexity and risks of electrical connections

More modules mean more connection points. Each connection point (including MC4 connectors between modules, terminals in the combiner box) is a potential source of failure.

If connectors are not installed properly, or age after long-term exposure to wind and rain, it may lead to increased contact resistance, causing local overheating or even DC arc faults.

Therefore, reducing the number of modules from 40 to 10 is equivalent to reducing the system's potential failure points by three-quarters, significantly improving long-term reliability.

Direct impact on mounting system and installation costs

The cost of the mounting system (rails, clamps, brackets, etc.) and installation labor hours are strongly related to the number of modules.

l Material cost: Installing 40 modules typically requires more rails to fix these more dispersed, numerous small units. Although the mounting cost per module might be lower, the total number is large, and the total cost may反而 exceed.

l Installation time: Installers need to move, position, level, and fix each module. The time spent handling 40 modules far exceeds the time spent handling 10 modules.

Matching issues with inverters

Inverters have specific input voltage and current ranges; the series-parallel design of the modules must meet these requirements.

l 100W modules: Their open-circuit voltage and operating voltage are usually lower. To reach the minimum voltage required for the inverter to start, a relatively large number of modules need to be connected in series.

l 400W modules: Their electrical parameters (operating voltage typically in the 30-40V range) are tailored for modern grid-tied inverters. Fewer modules (e.g., 8-10) in series can reach the inverter's optimal operating voltage range (e.g., 300-500V), making the system run more stably and less sensitive to voltage fluctuations.

Amplified impact of shading on the system

When part of a module's cells are shaded, its power generation capacity drops sharply.

l In a system composed of 40 x 100W modules, if one module is shaded, it affects about 2.5% of the system's total output.

l In a system composed of 10 x 400W modules, if one module is shaded, it will affect 10% of the system's total output.

Ease of system maintenance and troubleshooting

The convenience of system maintenance is also directly related to the number of modules.

l Troubleshooting: When a system composed of 40 modules has abnormal power generation, technicians need to check 40 modules and their corresponding connection points one by one, which is a huge workload. In a system with only 10 modules, locating the problematic module is much more efficient.

l Monitoring granularity: Configuring string-level monitoring is more economical for large systems. For systems composed of very low-power modules, the cost of configuring fine-grained monitoring may be too high, making precise operation and maintenance management impossible.

Adaptability to different application scenarios ultimately determines the choice

The system-level impact ultimately points the choice toward different application scenarios.

l 100W-level module systems: Their value lies in ultimate flexibility and modularity. They are suitable for users whose power demand will gradually increase, with budgets allocated in stages, or for scenarios with extremely dispersed and irregular space (e.g., RV roofs, small boat decks).

l 400W-level module systems: Their advantage lies in maximizing the total system power and energy generation revenue on a fixed, contiguous available area.

Daily Energy Yield

In a region with an average of 4.5 peak sun hours per day (like California, USA), a nominal 100W solar panel, after accounting for approximately 15% line loss and inverter efficiency loss, has an actual daily energy yield of about 380Wh.

This is only enough to charge a 60Ah 12V car battery by about 50%, or power an energy-efficient refrigerator (annual consumption ~250kWh) for about 1.5 days.

A 400W solar panel, under the same conditions, can yield up to 1.53kWh per day, which is 4 times that of the 100W panel.

This is sufficient to directly support the full-day operation of the aforementioned energy-efficient fridge (daily consumption ~0.68kWh) and simultaneously power lighting, routers, and other devices.

Core Variables

Peak Sun Hours determine the power generation potential of a solar system.

It is not a simple concept of sunrise to sunset time, but a conversion of the solar radiation energy of different intensities throughout the day into equivalent hours under Standard Test Conditions.

These Standard Test Conditions refer to: under the AM1.5 spectral distribution, an irradiance of 1000 watts per square meter, with the ambient temperature controlled at 25°C.

This value is measured using a pyranometer installed on a horizontal plane.

Weather stations continuously record the hourly solar radiation, in kWh/m².

For example, if the total radiation recorded at a location on a certain day is 5.5 kWh/m², then the peak sun hours for that day is 5.5 hours.

The total solar energy that day is equivalent to shining under standard test conditions for 5.5 hours.

How latitude changes the "intensity" of sunlight

Latitude is the primary factor causing uneven global solar distribution. Its influence is mainly reflected in the solar altitude angle.

Sunlight in high-latitude regions must pass through a thicker atmosphere; a greater proportion of energy is scattered and absorbed along the way, resulting in reduced intensity reaching the ground.

l Low-latitude regions (e.g., Florida, latitude ~25°N): The sun's path in the sky is high, and sunlight is close to direct. The annual average peak sun hours can typically reach 5.0 to 5.5 hours.

l Mid-latitude regions (e.g., New York State, latitude ~40°N to 45°N): The solar altitude angle varies significantly with the seasons. The annual average peak sun hours drop to 4.0 to 4.5 hours. Compared to Florida, a solar panel of the same power will produce about 15%-20% less annual energy here.

l High-latitude regions (e.g., Anchorage, Alaska, latitude ~61°N): The sun is at a low angle year-round, and sunlight intensity is weak. The annual average peak sun hours may be only 2.5 to 3.0 hours.

Seasonal Impact:

The fluctuation of sun hours within a year can far exceed expectations. This fluctuation is mainly caused by the tilt of the Earth's axis and changes in the Earth-Sun distance.

Season | Typical Northern Hemisphere Region (e.g., Illinois, latitude 40°N) | Typical Southern Hemisphere Region (e.g., Christchurch, NZ, latitude 43°S) |

Summer (Jun-Aug) | Peak sun hours can reach 6.0-6.5 hours. Long days, high sun altitude, the golden period for generation. | Peak sun hours drop to 2.0-2.5 hours. This is winter, with short days and low sun altitude. |

Winter (Dec-Feb) | Peak sun hours plummet to 2.5-3.0 hours. Short days, oblique sunlight, and often affected by snow/ice cover. | Peak sun hours rise to 5.5-6.0 hours. This is summer, and the generation reaches its peak. |

Taking Germany (latitude ~47°N-55°N) as an example, the daily peak sun hours in July can be more than 4 times that of December.

From Desert to Ocean:

Even at the same latitude, local climate and geographical features can cause significant differences.

l Arid Desert Climate (Phoenix, Arizona): Annual average peak sun hours can exceed 6.5 hours, among the highest in the world.

l Mediterranean Climate (Los Angeles, California): Annual average peak sun hours are about 5.8 hours.

l Marine Climate (Seattle, Washington): Influenced by Pacific warm, moist air currents, cloudy and rainy weather is frequent. Annual average peak sun hours are only 3.5 to 4.0 hours. The number of overcast days per year exceeds 200, posing a continuous challenge to the daily output of solar systems.

l High Altitude Region (Denver, Colorado, altitude ~1600 meters): Known as the "Sunshine State". High altitude, thinner atmosphere, weaker filtering of sunlight. Despite not being low latitude, its annual average peak sun hours can exceed 5.5 hours, comparable to many low-latitude regions.

How to get specific data for your street

When planning a solar system, using localized historical data is more reliable than national averages. Here are ways to get accurate data:

1. NASA's SSE Database: Provides monthly and daily average solar radiation data for latitude/longitude grid points worldwide, with a time span of over 20 years.

2. NREL's PVWatts Calculator: In addition to providing local typical solar data, it can simulate and calculate annual energy generation estimates based on your input system parameters. You just need to enter an address or zip code.

3. Local Weather Station Data: Some official or research weather stations that have long-term records of solar radiation can provide the most accurate localized data.

Efficiency Losses

How the charge controller consumes some electricity

The charge controller is responsible for efficiently charging the cell with the unstable power generated by the panel. Its working mode directly affects energy harvest.

l PWM Controller: Works like a fast-switching circuit, forcibly pulling the panel voltage down close to the cell voltage. In this process, the panel cannot operate at its Maximum Power Point (MPP), leading to 10%-30% energy loss. For example, a 100W panel operating at 18V MPP, when charging a 12V cell via PWM, might only deliver 70-80W actual output.

l MPPT Controller: Through a built-in DC-DC converter circuit, it can actively track and keep the panel operating at its MPP (e.g., 18V), while charging the cell at the required voltage (e.g., 14V) and a higher current. Its own conversion efficiency is typically as high as 97%-99%. Under the same conditions, an MPPT controller can harvest 15%-25% more energy than a PWM controller, especially when the weather is cold and the panel voltage is higher.

Wires: Thicker isn't always better

Loss size is determined by the formula P_loss = I² × R, where I is the current and R is the wire resistance.

l Impact of Voltage: When transmitting the same power, higher voltage means lower current. A 12V/400W system has an operating current of about 33.3A. A 48V/400W system has an operating current of only 8.3A. According to the formula, reducing the current to 1/4 reduces the power loss to 1/16 of the original.

l Distance & Wire Gauge: Assume a 12V system uses a 5-meter long 10AWG cable (resistance ~0.0032 ohms/meter) to connect a 100W panel, current 8.3A. Line loss calculated as: (8.3A)² × (5m × 2 × 0.0032Ω/m) ≈ 2.2W, loss rate about 2.2%. If a thinner 14AWG cable is used (resistance ~0.0051 ohms/meter), the loss increases to about 3.5W (3.5%).

The hidden cost of cell charging and discharging

l Lead-Acid Batteries: At the end of the charging cycle, part of the electrical energy is used for electrolyzing water to produce gas. Charging efficiency is typically 80%-85%. To store 10 kWh into the cell, only 8-8.5 kWh is actually usable. During discharge, internal resistance also consumes some energy.

l Lithium-ion Batteries: Their electrochemical reaction efficiency is higher, with overall charge-discharge efficiency reaching 95%-98%.

The cost of inverter conversion

l Converting the cell's DC power to AC power for household appliances requires the inverter to consume energy itself.

l Standby Power Consumption: Even with no load, the inverter's internal circuits are working, typically consuming 10-50 watt-hours per day.

l Conversion Efficiency Curve: Inverter efficiency is not a fixed value but varies with the load rate. It is usually highest ( 90%-95%) when the load rate is 50%-80%, and can drop sharply to below 80% at light loads (e.g., 10%).

Immediate impact of temperature and shading

Temperature Coefficient: Solar panels usually have a negative power temperature coefficient, about -0.3% to -0.5%/°C. When the panel surface temperature rises from the standard 25°C to 60°C in midsummer, its output power decreases by (60-25) × 0.4% ≈ 14%.

Amplification Effect of Shading: A standard 60-cell module typically has 3 parallel "strings" internally. Even a small shadow covering a few cells in one string can cause the current of the entire string to drop, resulting in a power loss of up to one-third for the module.

Slow erosion of dust accumulation

l Dust, pollen, bird droppings, and other pollutants on the panel surface block light, causing persistent power generation loss.

l In areas with little rain and lots of dust, monthly power loss due to dust accumulation can reach 3%-6%.

l Studies show that after a rainfall, the power generation of cleaned panels can be instantaneously over 5% higher than uncleaned panels.

Energy Yield Comparison

Performance differences under different sunlight conditions

The energy yield of a solar panel is directly affected by geographic location and seasonal variations.

In Phoenix, Arizona (annual average 6.5 peak sun hours), a 100W mono-crystalline panel yields about 520Wh daily, while the same panel in Seattle, Washington (annual average 3.5 peak sun hours) yields only 280Wh daily.

Looking at quarterly data, a 400W panel system in California can yield up to 2.6 kWh daily in summer, but drops to around 1.5 kWh in winter.

This seasonal fluctuation requires system design to consider the generation capacity in the worst month, not the annual average.

Substantive difference in efficiency per unit area

When comparing 100W and 400W panels, the difference in physical size cannot be ignored.

A typical 100W mono-crystalline panel measures about 1000×540mm, with a power density of about 185 W/m².

Modern 400W panels use large-size silicon wafers like 166mm or 182mm, measuring about 1760×1040mm, achieving a power density of 218 W/m².

A 400W panel can generate over 15% more electricity per square meter of roof area.

This difference in efficiency per unit area has practical significance for installation scenarios with limited roof space.

On a standard residential roof (about 20 m² usable area), a maximum of about 12 x 100W panels (total capacity 1.2kW) can be installed, while using 400W panels allows installing about 16 panels (total capacity 6.4kW), increasing the system's total generation capacity by over 400%.

Comparison of power supply duration for different load types

The difference in energy yield is directly reflected in the ability to support various electrical devices. The following is a comparison of continuous power supply time under standard test conditions (4.5 peak sun hours, 85% system efficiency):

Electrical Device | Rated Power | 100W System Daily Supply Time | 400W System Daily Supply Time |

LED Lighting (10W) | 10W | 32.5 hours | 130 hours |

Laptop (65W) | 65W | 5 hours | 20 hours |

Refrigerator (avg. 100W) | 100W | 3.25 hours | 13 hours |

Mini Air Conditioner (500W) | 500W | Not feasible | 2.6 hours |

The data shows that a 400W system can provide nearly continuous power supply for small devices and support daily use of medium loads, while a 100W system is only suitable for intermittent, low-power consumption scenarios.

Energy yield growth pattern during system expansion

Two 100W panels in parallel have a theoretical capacity of 200W, but due to factors like resistance imbalance in parallel circuits, the actual output is typically 190-195W.

A single 400W panel, without matching issues, has a stable actual output of 380-390W.

When expanding the system to a 2000W scale, a system using 5 x 400W panels might have line losses of about 2-3%, while a system using 20 x 100W panels, due to complex wiring, might have losses of 5-8%.

In large-scale systems, the overall efficiency advantage of high-power panels becomes more evident.

Power generation capability retention in cloudy/rainy weather

Under adverse weather conditions, the performance degradation of panels of different specifications varies.

Under thick overcast conditions, a 100W poly-crystalline panel output might drop to 10-15% of its rated power, while a 400W mono-crystalline panel, with better low-light performance, can typically maintain 15-20% output.

Actual test data shows that during three consecutive days of rainy weather, a 100W system yielded only 0.12 kWh daily on average, while a 400W system could still maintain an average daily output of 0.68 kWh, enough to sustain basic power needs like routers and phone charging.

Impact of different installation methods on actual energy yield

Energy yield is also constrained by the installation tilt angle. 100W portable panels are often laid flat, reducing annual energy yield by over 20% compared to installation at the optimal angle.

400W fixed-installation systems can optimize the tilt angle (usually set to the local latitude value), and increase the angle appropriately in winter to improve the reception efficiency of low-angle sunlight.

Actual data shows that at 40 degrees latitude, a 400W system with an adjustable tilt angle yields 25-30% more annual energy than a flat installation.

If a single-axis tracking system is used, energy yield can be further increased by 15%, but this option is clearly only suitable for fixed-installation, high-power systems.

Annual energy yield degradation comparison

High-quality mono-crystalline panels degrade about 2% in the first year, and about 0.5-0.8% annually thereafter.

A 100W panel's actual power is about 93W after five years, while a 400W panel drops to 372W.

Although the degradation rate is similar, the difference in the absolute power loss is significant: the 100W system loses 7W of generation capacity over five years, while the 400W system loses 28W, which is equivalent to losing the full generation capacity of a 30W panel.

This degradation characteristic needs to be considered during the system design phase, especially for systems planned for use over 10 years, appropriate power redundancy should be reserved.

It is usually recommended to design the system size based on the expected energy yield after 10 years to ensure long-term use reliability.

Typical Dimensions

The physical size difference between 100-watt and 400-watt solar modules is significant, which directly determines their application scenarios and installation requirements.

A 100-watt module is typically about 1050 mm x 690 mm x 35 mm, with an area of about 0.72 square meters and a weight of 8-10 kg.

A 400-watt module measures about 1760 mm x 1040 mm x 35 mm, with an area of about 1.83 square meters and a weight of 21-23 kg.

The area of a 400W module is about 2.5 times that of a 100W module, but its power is 4 times greater, demonstrating higher power density.

Comparing Physical Dimensions

Some easily overlooked dimensional details

Beyond the conventional length, width, and height, the following dimension-related details are equally important:

l Frame and Mounting Hole Positions: The aluminum frame of a 100W module is usually narrower and lighter, with simple mounting hole designs, typically compatible with universal Z-brackets. For 400W and higher power modules, the frame is wider and sturdier to provide necessary structural support.

l Junction Box Size and Location: The junction box of a 100W module is usually smaller and located on the edge of the module's backsheet, facilitating wiring and reducing the risk of damage during stacking or transport. The junction box of a 400W module is larger (may contain diodes and thicker cables), and its position is designed to minimize cable losses during series connection.

l Practical Limits for Transport and Handling: A standard 400W module (about 1.8m long, 1m wide) is typically the practical limit for handling by one person. A width exceeding 1 meter may cause difficulties when passing through standard residential doorways or stairwell corners, requiring pre-measurement of the path. Handling and moving a 100W module (about 1m long, 0.7m wide) indoors presents almost no obstacles.

How size differences change the installation process

l Feasibility of Single-Person Work: Installing a single 100W module is a typical one-person task. The installer can easily lift it into position and secure it alone. Installing a 400W module, especially on a sloped roof, is strongly recommended as a two-person job—one person supports and passes the module from below, while the other guides and secures it from above—ensuring safety and installation accuracy.

l Installation Efficiency and Labor Cost: Suppose you need to install a system with a total capacity of 2 kilowatts.

l Using 100W modules: Requires installing 20 pieces. This involves 20 instances of moving, 20 instances of positioning, tightening 80 screws (assuming 4 fixation points per module), and 20 cable connections.

l Using 400W modules: Requires installing only 5 pieces. The corresponding moving, positioning, fastening, and wiring workload is reduced to a quarter.

l Requirements for the Roof Surface: 400W modules require a large, continuous, unobstructed installation surface. If the roof has multiple skylights, ventilation pipes, or complex parapet walls, finding positions that can accommodate entire large modules becomes difficult. In such cases, multiple 100W modules can be flexibly arranged like a jigsaw puzzle to navigate around these obstacles, utilizing irregular space more fully.

The practical significance of power density

Power density (Watts per square meter) is a hard indicator of technological advancement, and its real-world impact is reflected in two aspects:

Power Generation Capacity in Space-Constrained Scenarios: Assume an RV roof has only 3 square meters of effective installation area.

Using 100W modules (power density ~139 W/m²): A maximum of 4 pieces can be installed, total power ~400 watts.

Using 400W modules (power density ~219 W/m²): One piece can be installed, total power 400 watts. But if space allows, using a higher power density 380W or 400W module might achieve higher total power output in the same area.

Total Area Required to Reach Target Power: For a residential system targeting 6 kilowatts.

Using 100W modules (0.72 m²/piece): Requires 60 modules, occupying a total roof area of about 43.2 square meters.

Using 400W modules (1.83 m²/piece): Requires 15 modules, occupying a total roof area of about 27.5 square meters.

Area Difference: Using 100W modules occupies about 15.7 square meters more roof area than using 400W modules, which is almost the area of a standard parking space.

Chain reaction caused by dimensions on the system

The physical size of the module is the starting point for system design and triggers a series of chain reactions:

Mounting Structure Load: 400W modules are heavier individually and have a larger wind exposure area. This not only requires the mounting material itself to be stronger but also places higher demands on the roof's load-bearing capacity.

Hotspot Effect Risk: Larger area modules may experience more significant hotspot effects when partially shaded (e.g., by leaves, bird droppings), requiring higher performance and better configuration of bypass diodes.

Maintenance and Replacement: If a 400W module in the system needs replacement due to damage, the system instantly loses 400W of generation capacity, and the replacement operation itself is more complex due to the module's weight and size.

Module Dimensions

Size Differences in Numbers

Let's first look at the typical dimensions of 100W and 400W modules side by side.

This data comes from the mainstream product specification sheets in the current North American and European markets.

Specification Parameters | 100W Module (Typical Monocrystalline Specification) | 400W Module (Typical High-Efficiency Monocrystalline Specification) |

Length (mm/inch) | 1050-1100 mm / 41.3-43.3 in | 1750-1800 mm / 68.9-70.9 in |

Width (mm/inch) | 670-690 mm / 26.4-27.2 in | 1040-1060 mm / 40.9-41.7 in |

Thickness (mm/inch) | 35-40 mm / 1.4-1.6 in | 30-35 mm / 1.2-1.4 in |

Estimated Area (m²/ft²) | ~0.72 m² / ~7.75 ft² | ~1.83 m² / ~19.7 ft² |

Estimated Weight (kg/lbs) | 8-10 kg / 17.6-22 lbs | 21-23 kg / 46.3-50.7 lbs |

From the table, several key points can be seen:

· The length of the 400W module increases by about 70%, and the width increases by about 50%. This makes its total area about 2.54 times that of the 100W module.

· In terms of weight, the 400W module is about 2.3 times that of the 100W module.

· The thickness of the 400W module is sometimes thinner, thanks to more advanced encapsulation technology, which helps reduce weight and material costs.

How Dimensions Affect Your Installation Process

The physical size of the module determines the complexity and cost of installation.

1. Feasibility of Handling and Operation

· A single 100W module (about 10 kg) can be relatively easily carried up a ladder by one adult and positioned and secured on the roof alone.

· A single 400W module (about 22 kg), with its dimensions (nearly 1.8 meters long and 1 meter wide), makes single-person handling both difficult and dangerous.

2. Requirements for the Installation Surface

· 400W modules require a large, continuous, and unobstructed installation plane. If your roof has multiple skylights, ventilation pipes, or chimneys, finding positions to flatly install multiple large modules may be difficult.

· 100W modules are much more flexible. They can adapt to irregular roof spaces like a puzzle, easily bypassing obstacles. This is a significant advantage for RV curved roofs, small sheds, or roofs with complex structures.

3. Installation Time and Hardware Costs

· Assuming the installation of a 4 kW system.

o Using 100W modules requires installing 40 pieces. 40 handlings, 40 positionings, 160 fixing point fastenings (assuming 4 bolts per piece), and 40 electrical connections.

o Using 400W modules requires only 10 pieces. The workload is reduced to a quarter, and the installation time might be shortened from 3-4 days to 1-2 days.

· Fewer modules also mean fewer mounting rails, cables, and connectors. The reduction in these "balance of system" costs is considerable.

The Relationship Between Size and Power Density

Power density (W/m²) is an efficiency metric that links size and power.

· 100W Module Power Density: 100W / 0.72㎡ ≈ 139 W/㎡

· 400W Module Power Density: 400W / 1.83㎡ ≈ 219 W/㎡

The essence of this difference is that 400W modules integrate more efficient technologies (such as PERC, TOPCon cells, multi-busbar technology) within a unit area, thus generating more electricity.

For owners with a fixed installation area, choosing high-power density modules means achieving a higher total power generation on a limited roof.

For example, on a 20 square meter roof, using 219 W/㎡ modules compared to 139 W/㎡ modules can increase the total capacity by about 1600 watts.

Some Easily Overlooked Size Details

Besides length, width, and height, there are other size-related factors to consider:

· Frame and Mounting Hole Positions: High-power modules have sturdier frames, and the mounting hole positions must match specialized brackets. Self-modification or using mismatched brackets may pose risks.

· Junction Box Size and Position: The junction box of a 400W module is larger, and its position is designed to optimize cable routing. During dense installations, ensure that the junction boxes of adjacent modules do not interfere with each other.

· Maintenance and Replacement: If a 400W module in the system is damaged, it means the system immediately loses 400W of power generation capacity, and replacement is more laborious. In contrast, replacing a 100W module has a smaller impact and is easier to handle.