Photovoltaic Cell Technology, Efficiency and Applications

Monocrystalline PERC is the mainstream, while TOPCon (tunneling oxide passivation) is becoming the upgrade direction; mass production efficiency is 23%—25% (NREL), and TOPCon laboratory efficiency is >26% (ISFH). It is used in ground power plants, distributed rooftops, and BIPV (such as Tesla Solar Roof), with proven efficiency improvements of 15% (industry case).

Technology

Photovoltaic cell technology is centered on the photovoltaic effect, converting light energy into electrical energy through semiconductor materials.

Among mainstream technologies, crystalline silicon accounts for over 90% of global installations. HJT lab efficiency is 26.81% (SunPower), TOPCon mass production is 25%+ (LG); thin-film CdTe mass production is 22%+ (First Solar), flexible CIGS is 23.35% (Solar Frontier); perovskite single-junction is 26.1% (UNIST), tandem is 32.5% (Oxford PV).

Technological iteration has reduced the Levelized Cost of Electricity (LCOE) by 80%, with a theoretical efficiency limit exceeding 45%, actively reshaping the global energy structure.

Principle

Collision of Photons and Semiconductor Materials

Sunlight contains photons of different energies, measured in electron volts (eV). The calculation formula is E=hc/λ (h is Planck's constant 6.626×10⁻³⁴ J·s, c is the speed of light 3×10⁸ m/s, λ is the wavelength).

Only when the photon energy > the semiconductor's bandgap (Eg) can it "kick" an electron from the valence band to the conduction band, creating a free electron.

For example, silicon's Eg=1.1eV, corresponding to absorbed photon wavelengths <1127nm (it can absorb some infrared light too); Cadmium Telluride (CdTe) Eg=1.45eV, corresponding to wavelengths <855nm, making it better at capturing infrared light.

The solar spectrum energy distribution is: Ultraviolet (400nm) 5%, Visible light (400-700nm) 43%, Infrared (700-2,500nm) 52%.

Silicon can absorb light from 400-1,100nm, covering visible and near-infrared light, which accounts for over 80% of total solar irradiance.

Electron-Hole Pairs

After an electron jumps, it leaves a positively charged vacancy in the valence band called a "hole."

The electron and hole form an "electron-hole pair," both carrying unit charge (electron -1.6×10⁻¹⁹C, hole +1.6×10⁻¹⁹C), like a temporary pair.

However, their lifetime is short. At room temperature, the average lifetime of an electron-hole pair in silicon is about 1 microsecond (inferior materials <0.1 μs).

If not separated promptly, they recombine, and the energy is lost as heat.

Recombination is of two types: bulk recombination (due to defects inside the material) and surface recombination (due to defects at the material's edge or interfaces).

High-quality silicon wafers have bulk recombination rates <10 cm/s.

Surface recombination rates can be reduced from 10³ cm/s to below 10 cm/s with passivation layers (even <1 cm/s for HJT cells).

PN Junction Separates Charges

P-type semiconductor is doped with boron (electron-deficient), having many holes; N-type is doped with phosphorus (electron-rich), having many electrons.

When they contact, electrons from the N-region diffuse into the P-region, and holes from the P-region diffuse into the N-region.

A "space charge region" (depletion layer) forms at the junction, with one side positively charged (N-region loses electrons) and the other negatively charged (P-region gains electrons), creating a built-in electric field (direction N→P).

Efficiency depends on three key parameters:

Photovoltaic cell efficiency (η) = (Output electrical power / Incident light power) × 100%, specifically broken down into three parameters:

l Short-circuit current density (Jsc): The maximum current generated per unit area of the cell, depending on photon absorption and charge separation efficiency. Monocrystalline silicon Jsc is about 42 mA/cm² (under AM1.5 standard irradiance 1000 W/m²). Perovskites, due to high absorption coefficient (100 times that of silicon), can achieve Jsc of 26 mA/cm² (with a thickness of only 0.5μm, whereas silicon requires 180μm).

l Open-circuit voltage (Voc): The voltage when the cell has no load, determined by the material's bandgap and the built-in electric field. Silicon Voc is about 0.7V (Eg=1.1eV, theoretical limit 1.1V). HJT cells using intrinsic amorphous silicon passivation layers have achieved Voc breakthroughs of 0.75V (SunPower data), close to 70% of the theoretical value.

l Fill Factor (FF): The ratio of the actual maximum power to Jsc×Voc, reflecting charge collection efficiency. High-quality cells have FF > 0.8. Perovskites, due to many interface defects, typically have FF around 0.75 (lab max 0.83).

Different material bandgaps determine which light is captured

If Eg is too small (e.g., Germanium 0.67eV), excess photon energy becomes heat; if Eg is too large (e.g., GaAs 1.42eV), only short-wavelength light is absorbed, wasting infrared energy.

The ideal Eg should match the solar spectrum peak (500nm, corresponding to 2.48 eV), but is practically limited by material stability. For example:

l Monocrystalline silicon Eg=1.1eV, theoretical efficiency上限 (upper limit) 29.4% (Shockley-Queisser limit);

l CdTe Eg=1.45eV, theoretical limit 28.5%;

l Perovskite (MAPbI₃) Eg=1.55eV, theoretical limit 31.4%;

l Tandem cells (Perovskite + Silicon): Upper perovskite layer Eg=1.6eV captures blue light, lower silicon layer Eg=1.1eV captures red light, theoretical efficiency exceeds 45% (current lab 32.5%).

Mainstream Technologies

Crystalline Silicon Cells:

Crystalline silicon is used in over 90% of global PV installations, divided into monocrystalline and multicrystalline silicon, differing in wafer purity.

Monocrystalline Silicon: Efficiency keeps increasing, upgraded technologies compete for market share

Monocrystalline wafer purity >99.9999%, fewer defects, inherently higher efficiency than multicrystalline. Current mainstream upgrade technologies include three:

l PERC (Passivated Emitter and Rear Cell): Adds an aluminum oxide passivation layer on the back of the silicon wafer to reduce electron recombination. LG mass production efficiency 24.5%, 1.5% higher than traditional BSF cells, silver paste consumption 1.2g/W (traditional 1.5g), cost reduced by 10%.

l TOPCon (Tunnel Oxide Passivated Contact): Uses a 1-2nm silicon oxide + polysilicon layer instead of the traditional diffused junction, offering better passivation. LG mass production efficiency 25.2%, open-circuit voltage 0.73V (PERC 0.71V), wafer thickness 180μm, thicker than HJT but thinner than traditional.

l HJT (Heterojunction): Coats both sides with amorphous silicon film, forming natural passivation. SunPower lab efficiency 26.81%, mass production 24.5%, wafers thinned to 110μm (traditional 180μm), entire process low temperature <200°C (traditional >800°C), warp rate reduced by 50%, silver paste consumption 0.8g/W (30% less than PERC), but equipment investment is 20% more expensive.

Multicrystalline Silicon:

Multicrystalline silicon is produced by ingot casting, purity 99.999%, has many grain boundary defects, efficiency lower than monocrystalline.

Q CELLS mass production efficiency 23%, open-circuit voltage 0.68V, wafer thickness 200μm, cost 15% lower than monocrystalline, but efficiency drops faster under low light (2% lower than monocrystalline at 200W/m²).

Market share has shrunk from 30% to 5%, mainly used in price-sensitive regions like India and Southeast Asia.

Thin-Film Cells: Thin, light, flexible, targeting special applications

Thin-film cells are a few micrometers thick (vs. 180μm for crystalline silicon), using materials like Cadmium Telluride, Copper Indium Gallium Selenide, Perovskite, emphasizing lightweight, flexibility, and good low-light performance.

CdTe (Cadmium Telluride):

Uses glass substrate, deposits 2-3μm thick CdTe film by close-space sublimation. Mass production efficiency 22% (First Solar Series 6 module), maintains over 85% efficiency under low light (200W/m²), hot spot effect 30% lower than crystalline silicon (less prone to local overheating).

Holds 40% market share in the US. Module lifespan 25 years, annual degradation 0.5% (crystalline silicon 0.8%). Disadvantage: contains cadmium, high environmental disposal cost ($0.5 per module recycling fee).

CIGS (Copper Indium Gallium Selenide):

Divided into rigid (glass substrate) and flexible (stainless steel/plastic substrate). Solar Frontier rigid module mass production efficiency 19.5%, flexible lab efficiency 23.35% (thickness 2μm), bend radius <5cm, can be attached to car roofs, tents for power generation.

However, global indium reserves <20,000 tons (China holds 50%), gallium is even scarcer. Currently testing indium-free formulations (using zinc tin oxide instead), but efficiency drops to 18%.

Perovskite:

Organic-inorganic hybrid material (e.g., MAPbI₃), absorption coefficient 100 times that of silicon. A 0.5μm thick perovskite film can absorb light (silicon requires 180μm).

UNIST lab single-junction efficiency 26.1%, prepared by solution spin-coating (temperature <150°C), cost only 1/3 of crystalline silicon.

But many problems exist: ion migration causes annual degradation >10% (crystalline silicon <1%), sensitive to water and oxygen (encapsulation increases cost by 20%), lead toxicity (tin-based lead-free efficiency only 18%).

Oxford PV is developing perovskite-crystalline silicon tandem cells, efficiency 32.5%, planning mass production in 2024 (target efficiency 29%).

Emerging Technologies:

Tandem Cells: Stack layers to capture different light

Uses two materials with different bandgaps stacked together. The top layer captures short wavelengths (blue/violet light), the bottom layer captures long wavelengths (red/infrared light).

Besides perovskite-silicon (Oxford PV 32.5%), there are all-perovskite tandems (wide bandgap 1.8eV + narrow bandgap 1.2eV). KAUST lab efficiency 28.2%, theoretical limit 45%.

The problem is easy recombination at the interface between the two layers, yield <90% (crystalline silicon 98%).

Quantum Dot Cells: Tune bandgap with nanoparticles

Uses lead sulfide, cadmium selenide nanoparticles (diameter 2-10nm). Smaller size means wider bandgap, tunable to capture different light.

Suntech Power lab efficiency 18.1%, lower than crystalline silicon but lower cost (solution-based preparation). Also capable of "multiple exciton generation" (one photon generates 2 electrons), theoretical efficiency over 40%.

Efficiency

Efficiency refers to the percentage ratio of the output electrical power of a photovoltaic cell to the incident solar power, a direct indicator of photoelectric conversion capability.

The theoretical limit for single-junction cells (Shockley-Queisser) is 33.7%. Commercial silicon cell mass production efficiency is 20-23% (NREL 2023).

Each 1% increase in efficiency adds approximately 50 million kWh annual generation for a 1GW power plant (IRENA). Lab perovskite-silicon tandem cell efficiency reached 32.5% (HZB 2023). Efficiency improvements have contributed to a 40% reduction in PV LCOE over the past decade (IRENA).

Sources of Loss

Optical Losses:

Surface reflection is the most intuitive.

An untreated silicon wafer surface acts like a mirror, directly reflecting away 30% of sunlight (NREL 2022 data).

Later, anti-reflection coatings were applied, such as silicon nitride (SiNx) or titanium dioxide (TiO₂) multilayer films, using light interference to reduce reflectivity below 2%.

First Solar's CdTe modules go further, using nano-textured surfaces to reflect light back and forth within the cell, doubling the optical path length and increasing absorption by 1.5%.

Electrode shading stealthily steals area.

Metal gridlines are used to collect current but block 3%-8% of light (Fraunhofer ISE 2023).

SunPower's IBC cells place both positive and negative electrodes on the backside, completely eliminating front-side shading. The same area collects 1.2% more light than PERC cells, naturally leading to higher efficiency.

Long-wavelength light passes directly through.

45% of the solar spectrum is infrared light (wavelength >1100nm), with energy lower than silicon's bandgap (1.12eV). Silicon simply "ignores" these low-energy photons, watching them pass through the cell.

Labs have experimented using Germanium (bandgap 0.67eV) as a bottom cell to absorb long wavelengths, but germanium's high cost prevents large-scale use.

Electrical Losses:

Even if light enters, the generated electrons and holes might disappear before reaching the electrodes. This is electrical loss, accounting for 50%-60% of generated carriers. There are three main types.

Bulk Recombination: Poor "constitution" of the silicon wafer with inherent flaws. Impurities in the silicon wafer (e.g., iron, copper) or lattice defects (like cracks in ice) cause electrons and holes to collide and recombine. High-quality monocrystalline silicon has bulk recombination rates as low as less than 10¹⁰ defects per cm³ (Fraunhofer ISE 2023), but cheap multicrystalline silicon might have 10¹⁵ /cm³, resulting in a 3-5 percentage point efficiency difference.

Surface Recombination: "Traps" hiding in corners and edges. The edges after wafer cutting, the surfaces of textured structures, have many "dangling bonds" (unpaired atoms) that specifically capture electrons and holes. TOPCon cells coat the surface with an ultra-thin silicon oxide (SiO₂) + polysilicon layer, sealing these traps. Surface recombination velocity drops from over 1000 cm/s without passivation to below 10 cm/s (Maxeon 2023 data), immediately boosting efficiency by 0.5%.

Series Resistance: Wires too thin, current can't flow well. Electrons traveling through the silicon encounter resistance at metal contact points (e.g., silver paste solder points) and the silicon itself, like a clogged pipe. High series resistance causes the I-V curve's "fill factor" to drop from the ideal 0.85 to the measured 0.75-0.82. Meyer Burger uses copper plating instead of silver paste, reducing contact resistance by 30%, increasing efficiency by 0.3% (2023 report).

Thermal Losses:

Even if light is absorbed, after electrons receive energy, the excess portion turns into heat and is lost. This is thermal relaxation loss, accounting for 20%-30% of the absorbed light energy.

For example: A 300nm ultraviolet photon has energy 4.1 eV. Silicon's bandgap is only 1.12 eV, so the electron can only take 1.12 eV, the remaining 2.98 eV all becomes heat through lattice vibration (NREL 2022 simulation).

Ultraviolet + visible light accounts for 55% of the solar spectrum's energy, of which about 30% is wasted this way.

Multi-junction cells can mitigate this. For example, a triple-junction GaAs cell uses a top layer of InGaP (bandgap 1.9eV) to absorb blue light (just the right energy), a middle layer of AlGaAs (1.4eV) for green light, and a bottom layer of GaAs (0.7eV) for red light. Each layer takes only the energy it needs, reducing thermal loss to below 15% (NREL 2022 concentrator cell data).

Others are experimenting with hot carrier cells, aiming to collect electrons rapidly before thermal relaxation. Theoretically, thermal loss could be suppressed to 5%, but currently this is only achievable at liquid nitrogen temperatures (MIT 2023 lab result), far from practical application.

Efficiency Improvement

Replacing old materials with new ones

Perovskite single-junction cells have become a hot topic. Oxford PV achieved 26.1% lab efficiency in 2023, nearly catching up to the monocrystalline silicon limit (26.7%).

Its light absorption capability is 10 times that of silicon; a 200nm thick perovskite film can absorb 90% of visible light, whereas a silicon wafer needs to be 180μm thick.

Moreover, its bandgap can be tuned between 1.5-2.3eV, allowing absorption of either blue or red light as desired. However, stability is still being improved. Oxford PV's 2023 report stated the module T80 lifespan (time until efficiency drops to 80%) increased from 500 hours in 2015 to 5000 hours, still far from silicon cells' 25 years.

Multi-junction tandem cells split the solar spectrum for use. For example, the perovskite-silicon tandem made by HZB in 2023 uses a top perovskite layer (bandgap 1.68eV) to consume blue and green light, and a bottom silicon layer (1.12eV) for red and near-infrared light. The layers don't interfere, pushing efficiency to 32.5%.

Kaneka's all-perovskite tandem (two perovskite layers) in 2016 achieved 28% efficiency, with half the cost of silicon.

Even more impressive are triple-junction GaAs concentrator cells, measured by NREL in 2022 at 47.1% efficiency, used in desert power plants, generating 3 times more electricity per unit area than silicon cells.

Passivated contact materials put a "protective coat" on the silicon wafer. SunPower's TOPCon cells deposit a 1nm silicon oxide + 100nm polysilicon layer on the back of the wafer, suppressing surface recombination velocity from 1000 cm/s to below 10 cm/s, achieving mass production efficiency of 25.4% (2023).

Fraunhofer ISE's HJT cells are even more extreme, using an amorphous silicon layer for passivation, achieving 25.9% efficiency (2023), 2 percentage points higher than PERC.

Making light stay longer inside the cell

Light-trapping structures "trap" light in the cell. First Solar's CdTe modules have nano-textured surfaces, like dense tiny pyramids. Light entering reflects repeatedly, extending the optical path by 2 times, increasing absorption by 1.5%.

Labs use nanoimprinting to create even smaller structures (50nm scale), which can add another 1%.

Anti-reflection coatings give the cell "sunglasses." Ordinary glass reflectivity is 8%; coating with silicon nitride (SiNx) reduces it to 4%; multilayer coatings (e.g., SiNx+TiO₂) can reach below 2%.

SunPower's X-series modules use such coatings, measured reflectivity 1.9%, collecting 3% more light than uncoated modules.

Back-contact technology hides the electrodes. SunPower's IBC cells place both positive and negative electrodes on the backside. With no front gridline shading, the effective light-receiving area increases by 8%. Mass production efficiency is 22.7%, 1.2% higher than contemporary PERC.

LG's similar product achieves 23.1% efficiency, relying on laser grooving on the back for electrodes.

Making electrons move more smoothly

Selective contact materials only let electrons pass. Maxeon uses hydrogenated amorphous silicon (a-Si: H) plus silicon oxide as a contact layer. Electron transport rate >95%, holes are blocked, recombination rate <5 cm/s, 10 times lower than ordinary contacts, increasing efficiency by 0.5%.

Low-temperature electrode processes reduce resistance. Traditional silver paste requires sintering at 800°C, easily damaging the silicon wafer. Meyer Burger switched to copper electroplating, achievable at 200°C, reducing contact resistance by 30%, increasing efficiency by 0.3% (2023 report). Copper is cheaper than silver, also saving cost.

Smart tracking mounts keep light facing the cells directly. Array Technologies' dual-axis trackers follow the sun, increasing average daily generation by 20%-30% compared to fixed mounts. A 1MW plant in Arizona, USA, using these, generated 250,000 kWh more per year (NREL 2023 data).

2023 Overseas Mainstream Efficiency Improvement Technologies Comparison

Technology Type | Representative Company/Institution | Mass Production Efficiency (%) | Laboratory Efficiency (%) | Efficiency Improvement Principle Details |

Perovskite Single-junction | Oxford PV | - | 26.1 | Absorption coefficient 10x Si, tunable bandgap 1.5-2.3eV |

Perovskite-Silicon Tandem | HZB Institute | - | 32.5 | Top/bottom layers absorb blue/green + red light separately |

TOPCon (Passivated Contact) | SunPower | 25.4 | 26.0 (Fraunhofer) | Silicon oxide + polysilicon surface passivation |

HJT (Heterojunction) | Meyer Burger | 25.0 | 26.8 (Kaneka) | a-Si layer passivation + low-temp copper electrodes |

IBC (Back Contact) | LG | 23.1 | 24.5 (ISFH) | Back-side electrodes eliminate shading |

New tricks still being tested

Quantum dot cells: Absorb infrared light (not absorbed by silicon), MIT 2023 lab efficiency 18%, theoretically can reach 44%.

Hot carrier cells: Prevent electrons from converting excess energy to heat, MIT achieved 40% efficiency with liquid nitrogen cooling, not feasible at room temperature yet.

Perovskite-organic tandem: Fraunhofer ISE 2023 efficiency 28.7%, slightly more stable than pure perovskite.

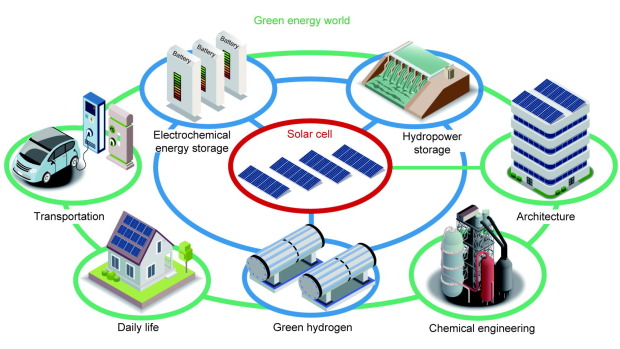

Applications

Global PV cell applications have formed a multi-dimensional implementation network.

In 2023, distributed generation accounted for 45% of the global total (IEA data), and the largest single centralized power plant reached 2.2GW capacity (Topaz project, California, USA).

BIPV module efficiency broke through 22% (SunPower A-series), off-grid systems cover over 5 million people without electricity in Africa, and rooftop PV on vehicles adds 50-80 km daily range for EVs.

Centralized Ground-mounted Power Plants

Site selection first considers sufficient sunlight

US National Renewable Energy Laboratory (NREL) data shows that regions with annual solar radiation exceeding 2200 kWh/m² (suitable for power plants) are mainly concentrated in the Sahara Desert in North Africa, the Arabian Peninsula in the Middle East, the Southwestern US (Arizona, Nevada), inland Australia, and the Atacama Desert in Chile.

For example, the Atacama Desert in Chile has over 3500 hours of annual sunshine, radiation reaching 2800 kWh/m², one of the highest global values; Yuma area in Arizona, USA, has annual radiation of 2500 kWh/m², more than double that of Germany (1100 kWh/m²).

These areas are either sparsely populated or have low land costs (desert land price in Nevada <$1,000 per acre), helping to dilute the unit cost of electricity generation.

How should mounts move to generate more electricity?

Mainstream types are two: Single-axis trackers (rotate around one axis, tracking east-west sun movement) and Dual-axis trackers (rotate around two axes, tracking sun altitude + azimuth).

US Nextracker's single-axis tracker holds over 35% market share. It keeps modules facing the sun, generating 15%-25% more electricity than fixed mounts.

For example, the 550MW Topaz plant in California uses single-axis trackers, generating 1.3 billion kWh annually.

With fixed mounts, it would only generate 1.04 billion kWh.

Dual-axis trackers are more efficient (25%-35% more generation) but 30% more expensive, mostly used in high electricity price regions.

For instance, parts of Spain's 500MW Núñez de Balboa plant tested dual-axis trackers, achieving up to 8% increased generation on peak days.

How far apart should modules be placed to avoid shading?

NREL experiments show that at 35 degrees north latitude (similar to Los Angeles, USA), with a module tilt of 30 degrees, the minimum front-to-back row spacing = module height × 1.8 (e.g., for a 2m high module, spacing at least 3.6m) to ensure no shading after 9 AM on the winter solstice.

In practical cases, the 1.18GW Noor Abu Dhabi plant in the UAE covers 8 km², designed with 4m module spacing, using nearly 4 million modules (400W each), arranged in neat arrays, like laying a "blue carpet" on the desert.

What do some major overseas power plants look like?

l Topaz Plant, California, USA (550MW): Grid-connected in 2014, uses First Solar thin-film modules (efficiency 14.5%), paired with SMA inverters. Annual generation 1.3 billion kWh, enough for 200,000 households for one year. Covers 25 km² (approx. 3500 football fields).

l Noor Abu Dhabi, UAE (1.18GW): Operational in 2019, one of the world's largest single-site plants. Uses bifacial double-glass modules (front efficiency 21.5%, backside gains 15% from sand reflection). Annual generation 2.1 billion kWh, reduces CO₂ emissions by 2.4 million tons (equivalent to taking 500,000 gasoline cars off the road).

l Charanka Solar Park, Gujarat, India (2245 MW): Built in phases, fully grid-connected by 2023. Uses Waaree modules (efficiency 22%), paired with ABB inverters. Annual generation 3.8 billion kWh, supplying 6 million rural households.

l Atacama Desert Plant, Chile (392MW): Operational in 2022. Uses SunPower Maxeon modules (efficiency 22.8%). Annual generation 980 million kWh, accounting for 12% of local grid renewable energy.

Plant Name | Country | Capacity | Module Type | Annual Generation (Billion kWh) | Area (km²) | Operational Year |

Topaz | USA | 550MW | First Solar Thin-film | 1.3 | 25 | 2014 |

Noor Abu Dhabi | UAE | 1.18GW | Bifacial Double-glass | 2.1 | 8 | 2019 |

Charanka Solar Park | India | 2245MW | Waaree Crystalline Si | 3.8 | 57 | 2023 |

Atacama Desert | Chile | 392MW | SunPower Maxeon | 0.98 | 12 | 2022 |

How much does one kWh cost?

The Levelized Cost of Electricity (LCOE) for centralized PV is already lower than fossil fuels.

2023 SEIA data shows LCOE for new plants in the US Southwest is about $0.03-$0.05/kWh (including land, modules, O&M), 30%-50% cheaper than natural gas power ($0.06-$0.08/kWh).

Due to its large scale (1.18GW), Noor Abu Dhabi's LCOE is as low as $0.028/kWh, making profit by selling electricity to the Dubai grid (electricity price $0.04/kWh).

How good is it really for the environment?

Using EPA standards, a coal plant emits 0.85kg CO₂ per kWh: A 1GW plant generates about 1.6 billion kWh annually (based on 1600 full load hours), reducing emissions by 1.36 billion kg CO₂ (1.36 million tons).

For example, Spain's Núñez de Balboa plant (500MW) reduces CO₂ by 680,000 tons annually, equivalent to planting 37 million trees.

But desert plants might affect local ecology, e.g., temperature under panels increases by 5-8°C.

So some projects leave 10% of the area vacant for planting drought-tolerant plants (like cacti) to help small animals find shade.

What challenges are faced now?

l Grid cannot handle it: PV generates a lot during the day, none at night. In 2022, California curtailed over 10% of PV generation due to surplus. The solution is adding storage, e.g., Topaz plant later added 100 MWh lithium batteries to store excess power for night use.

l Slow land approval: Building plants requires negotiations lasting over 10 years, e.g., a 2GW project in the Northern Territory delayed until 2030 for start.

How can it be improved in the future?

l Use more efficient modules: Perovskite-silicon tandem modules have broken 33% lab efficiency (Oxford PV). Future mass production could increase generation by 30% for the same area.

l Smart O&M saves costs: Use drones for inspection (5x faster than manual), AI predicts module failures (First Solar system can detect microcracks 7 days in advance), reducing O&M cost from $0.01/W to $0.005/W.

l "PV + Agriculture" saves land: A 1GW plant in Monterey County, California, grows lettuce (shade-tolerant varieties) under the panels, combining power generation and vegetable sales, increasing land utilization by 40%.

Distributed Generation

Is it cost-effective to install PV on factory/warehouse roofs?

Commercial and industrial (C&I) distributed PV is mainly installed on factory, warehouse, and logistics park roofs.

These have large areas (single factory roof often over 10,000 m²) and high electricity loads (24/7 production lines).

The "self-consumption" ratio can reach 60%-80%, resulting in significant electricity bill savings.

In 2023, US C&I distributed capacity accounted for 38% of new additions (SEIA data), with an average of 500kW-2MW per factory.

l What module type to choose: Prioritize high-efficiency crystalline silicon modules (efficiency 21%-23%), e.g., Tesla Solar Roof V3 (efficiency 22.5%, 25-year warranty). Gigafactory Nevada installed 10MW, generating 40 GWh annually, meeting 12% of the factory's electricity needs, reducing electricity cost from $0.08/kWh to $0.05/kWh. BASF chemical plant in Ludwigshafen, Germany, installed 10 MW on the roof (Q Cells brand, efficiency 22%), generating 12 million kWh annually, reducing CO₂ by 8000 tons (equivalent to burning 36 million fewer liters of diesel).

l Adding storage for stability: To prevent production disruption from power outages, many factories add lithium cell storage. An auto parts factory in Texas installed 2MW PV + 1MWh storage, able to power critical equipment even on cloudy/rainy days, reducing outage losses from $50,000/month to $5,000/month.

Country | Factory Case | Capacity | Module Efficiency | Annual Generation (MWh) | Self-consumption Ratio | Annual Savings ($10k) |

USA | Tesla Gigafactory | 10MW | 22.5% | 40,000 | 65% | 320 |

Germany | BASF Ludwigshafen Plant | 10MW | 22% | 12,000 | 70% | 96 |

Japan | Panasonic Himeji Factory | 5MW | 21.8% | 5,500 | 75% | 44 |

How much does it cost for an ordinary household to install PV?

Residential distributed PV (≤10 kW) is popularizing quickly overseas. In 2023, European residential capacity accounted for 55% of distributed total (SolarPower Europe). US average household system size is 8kW (SEIA).

Cost depends mainly on modules, inverter, and installation. Payback comes from saving electricity bills + selling surplus power.

l Netherlands: 7-year payback after subsidies: Average Dutch residential system 6kW (using JinkoSolar modules, efficiency 21.6%), cost €12,000 (including optional storage), government subsidy 30% (€3,600), actual expenditure €8,400. Annual generation 6000 kWh, self-consumption 4000 kWh (saving €800 on bills, electricity price €0.2/kWh), surplus 2000 kWh sold to grid (€0.1/kWh, earning €200). Total annual benefit €1,000, payback in 7-9 years.

l Australia: Penetration rate over 30%: A household in Queensland installed a 10kW system (Trina modules, efficiency 22%), cost A$15,000. Annual generation 15,000 kWh, self-consumption 10,000 kWh (saving A$2,500, electricity price A$0.25/kWh), surplus 5,000 kWh sold to grid (A$0.07/kWh, earning A$350). Annual benefit A$2,850, payback in 5.3 years (due to strong sunshine, 1800 annual full load hours vs Netherlands' 1000).

How does community solar work?

Community Solar allows residents without suitable roofs to participate by building a shared power plant, users buying electricity according to their share.

2023 US community solar capacity was 3.2GW (SEIA), with Minnesota having the highest share (40% of the state's distributed capacity).

l Operation Model: Community funds plant construction (e.g., 500kW), residents buy "virtual shares" (1 share = 1kW, annual fee $50), receiving a discount on corresponding electricity. A New York community plant (1MW) supplies 200 households, users save an average of $300/year on bills. The plant generates 1.2 million kWh annually, sells electricity to the grid for profit, operator takes 15% cut.

l Policy Support: US Federal Investment Tax Credit (ITC, 30% of investment cost), state-level net metering (high price for surplus power), ensure community solar returns of 6%-8%.

Where are installations high overseas?

l USA: 2023 distributed capacity 32GW (SEIA). California most (8GW), residential share 60%, due to good sunshine (annual radiation 1800 kWh/m²) + high net metering price ($0.3/kWh).

l Germany: Distributed accounts for 70% of total PV (2023 capacity 7.2GW). Average household system 5kW. The Renewable Energy Act mandates grid purchase of surplus power at €0.3/kWh (twice the wholesale price).

l Netherlands: Residential penetration 45% (2023). Government "SDE+" subsidy covers 30% of cost. Rooftop PV coverage over 60% (80% in rural areas).

Technical considerations

l Inverter choice: High-frequency or low-frequency? Small residential systems (≤10 kW) use high-frequency inverters (small size, high efficiency 97%). C&I uses string inverters (multiple MPPTs, adapt to complex roofs, efficiency 98.5%). German SMA string inverters hold 25% market share. US Enphase microinverters (one per module, prevents shading issues) hold 30% in residential.

l Is the roof load-bearing enough? Flat roofs may need reinforcement (load capacity ≥150 kg/m²). Sloped roofs use clamps. A warehouse roof in Florida had insufficient load capacity, added steel structure support (cost increase 10%) to avoid leakage risk.

What practical problems have been encountered?

l Aging roof leakage: Installing PV on old roofs can damage waterproofing. An Arizona supermarket leaked 3 years after installation, costing $20,000 to repair. Solution: roof renovation first (cost $5,000), then install PV, synchronizing lifespan to 25 years.

l Grid curtailment: During California's 2022 PV surplus, distributed generation was curtailed 10% between 2-4 PM, forcing users to abandoned light. Later, promoting "PV + storage" to store power for evening use reduced curtailment impact by 60%.

Building Integrated Photovoltaics (BIPV)

Replacing roof tiles with PV panels

BIPV roofs replace traditional tiles or color steel sheets with PV modules, providing both weather protection and power generation.

2023 global BIPV roof capacity accounted for 55% of total BIPV (Grand View Research). Module efficiency 20%-23%, lifespan 25 years (synchronized with traditional roofs).

l PV Tiles: Zurich Airport terminal uses SunPower Maxeon 6 PV tiles (efficiency 22.8%, 350W per tile), replacing ceramic tiles over 30,000 m² roof. Annual generation 3 million kWh, supplying 10% of airport lighting, 20% more expensive than traditional tiles but saves €4 million in electricity bills over 25 years. CertainTeed solar shingles (efficiency 19.5%) promoted in California homes. Single household installs 8 kW, generates 12,000 kWh/year, offsetting 60% of electricity bill.

l PV Color Steel Sheets: Popular in German industrial plants. E.g., BMW Leipzig plant roof uses Q Cells PV color steel sheets (efficiency 21%, 400W per sheet). 10MW installation generates 12 million kWh annually, meeting 15% of the plant's electricity. 15% more expensive than ordinary color steel sheets, but payback in 8 years from generation savings + sales.

Application Part | Country | Project Name | Module Type | Efficiency | Capacity | Annual Generation (10k kWh) | Effect |

Airport Roof | Switzerland | Zurich Airport Terminal | SunPower Maxeon 6 | 22.8% | 3MW | 300 | Supplies 10% airport lighting |

Factory Roof | Germany | BMW Leipzig Plant | Q Cells Color Steel Sheet | 21% | 10MW | 1200 | Meets 15% plant electricity |

Residential Roof | USA | California Single-family Home | CertainTeed Solar Shingle | 19.5% | 8kW | 1.2 | Offsets 60% household bill |

Façade generating electricity with some light transmission

BIPV façades use semi-transparent PV glass, providing both light transmission and power generation, suitable for commercial complexes, office buildings. 2023 European BIPV façade capacity accounted for 30% of BIPV total. Module transparency 20%-40%, efficiency 15%-18%.

l BMW Welt, Munich, Germany: Exterior wall uses semi-transparent PV glass (transparency 30%, efficiency 18%), area 5000 m², capacity 1MW. Annual generation 500,000 kWh, supplies exhibition hall lighting. 25% more expensive than ordinary glass curtain wall but achieved LEED Platinum certification (highest green building rating).

l Oslo Opera House, Norway: Uses PV sunshade louvers (efficiency 17%, 100W per louver) on the seaside façade. Reduces summer sunlight, lowering temperature by 15°C. Annual generation 80,000 kWh, powers backstage equipment.

Sunshades blocking sun while generating power

2023 US BIPV sunshade capacity grew 40% (SEIA). Single sunshade power 50-200W.

l An office building in Rotterdam, Netherlands: Exterior PV sunshade louvers (efficiency 19%, 150W each) cover 2000 m² façade, capacity 300kW. Annual generation 360,000 kWh, reduces AC load by 20%, saves €70,000/year on electricity.

l Stockholm Library, Sweden: Roof PV canopy (efficiency 20%, 200W per panel) doubles as a reader rest area roof. Capacity 500kW, annual generation 600,000 kWh, supplies 30% of library's electricity.

Which overseas buildings actually did this?

l Michigan State University PV Parking Lot, USA: Canopy uses SunPower semi-transparent modules (transparency 25%, efficiency 21%). 1.4MW capacity, annual generation 1.7 million kWh, powers campus EV charging stations and streetlights. Canopy parks 800 cars simultaneously.

l Hôtel de la Marine, Paris, France: Historical building renovation. Exterior uses custom BIPV glass (efficiency 16%, transparency 40%), preserving classical appearance while generating 120,000 kWh annually for museum lighting.

How much more expensive is BIPV compared to traditional materials?

BIPV initial cost is 20%-40% higher than traditional materials, but long-term payback comes from power generation. 2023 data:

l Roof: Traditional clay tile €100/m², PV tile €120-140/m²; Traditional color steel sheet €80/m², PV color steel sheet €95-105/m².

l Façade: Ordinary glass curtain wall €500/m², semi-transparent BIPV curtain wall €650-750/m².

l US NREL calculation: BIPV roof 25-year lifecycle cost is 15% lower than traditional roof (generation revenue offsets price difference). A German factory's 10MW PV roof paid back in 8 years (savings + sales).

Will it break down over time?

BIPV module lifespan is 25 years, synchronized with traditional materials. Maintenance focus is waterproofing and cleaning.

l Waterproofing: Installation uses EPDM rubber sealing strips (30-year weatherability). A California mall BIPV roof has a 10-year leak-free record.

l Cleaning: Dust affects generation by 10%-15%. Use robotic cleaning (e.g., German Kärcher PV cleaner, cleans 500 m²/hour), 50% cheaper than manual labor.

l Failure rate: Module microcrack rate <0.5%/year (SunPower data). Inverters use string type (efficiency 98.5%), failure rate <1%/year.

Actual electricity and carbon savings

l Electricity savings: Zurich Airport BIPV roof generates 3 million kWh/year, offsets 10% lighting electricity, saves €300,000 on bills.

l Emission reduction: BMW Leipzig plant 10MW BIPV generates 12 million kWh/year, reduces CO₂ by 9600 tons (based on 0.8kg CO₂/kWh from coal), equivalent to planting 530,000 trees.