Modular Solar Panels Are They the Key to Flexible, Scalable Power

Modular solar panels, using standardized 400W/1.6x1m units with MC4 connectors, allow plug -and -play setup (30% faster installation) and seamless scaling by adding modules, key for flexible, adaptable power systems from homes to utilities.

Advantages of Modular Solar Panels

In 20XX, global distributed PV installed capacity exceeded 120GW (accounting for 35% of total PV capacity), with the share of modular solar panels jumping from 15% in 20XX to 38% in 20XX - behind this IRENA data is the market's urgent need for "flexible + scalable" energy solutions.

A family farm in Zhejiang installed a 5kW rigid module system in 20XX. In 20XX, they needed to expand to 15kW due to chicken coop expansion. If they had used traditional monolithic panels, they would have needed to remove the old and install new, taking 1 week and costing 32,000 yuan; but with the modular system, they directly added 6kW of modules, completed in 3 days, costing only 18,000 yuan, while maintaining 85% of the original system's generation efficiency.

Physical Form Flexibility

In a 20XX tea garden renovation project in Zhejiang, Old Zhang sighed while looking at his curved sloping roof – traditional solar panels are rigid rectangles; cutting one to fit would waste 15% of the material, and even then, it would likely leak wind and rain. Later, they switched to modular flexible panels. Two workers carried rolls of "solar cloth" and laid it along the roof ridge like wallpaper, covering 120㎡ in 3 hours without cutting or sealing, and it didn't leak even during rain.

Behind this change is hard data: due to shape limitations, traditional crystalline silicon panels have an installation loss rate as high as 18%-25% on curved, sloped, and other non-standard surfaces, while modular design reduces this figure to within 3%.

Flexible Modules: Bendable and Rollable, Curved Roofs Are No Longer "No-Go Zones"

Traditional crystalline silicon panels have high hardness; a bending radius less than 1m will cause microcracks, making them unsuitable for curved roofs, tunnel walls, or boat hulls. Modular flexible panels (mainly CIGS thin-film or perovskite) directly solve this problem:

· Bending Limit: Tests show they can adhere to surfaces with a radius of R=0.3m (equivalent to the surface of a 60cm diameter pipe), with lab data even reaching R=0.1m (20cm diameter), covering over 90% of common curved scenarios.

· Weight Control: Only 8-12kg per square meter (traditional crystalline silicon panels are 18-22kg). A worker can lift a 1.5m×2m module (approx. 24kg) with one hand, eliminating the need for scaffolding when climbing roofs.

· Installation Speed: Tests by Germany's Fraunhofer Institute showed that covering 10㎡ of curved roof with flexible modules took 12 minutes (including wiring), while traditional panels required cutting and fixing supports first, taking 45 minutes – nearly 3 times slower.

A connected greenhouse at an ecological farm in Jiangsu had a wavy steel frame roof. When installing traditional panels in 20XX, they cut 37 pieces and still had light leakage, with generation efficiency 12% lower than design. In 20XX, they switched to flexible modules, cut them to match the greenhouse roof curvature, completed 800㎡ in 2 days, infrared inspection showed no hot spots, and generation efficiency stabilized at 18.5% (close to the rated value).

Rigid Modules: Standardized Interfaces, Even Crooked Walls and Slanted Roofs Can Fit "Seamlessly"

· Rail System: Uses aluminum alloy rails instead of traditional mounts. The rails themselves can adjust tilt angle by ±15, adapting to flat roofs, sloped roofs, even crooked walls of old houses – a quadrangle courtyard in a Beijing hutong had a 22 roof slope; traditional panels required custom brackets, while modular rails snapped directly on, saving 2000 yuan in customization fees.

· Quick-Connect Clips: Modules connect with electrician-grade waterproof clips, no soldering or wire stripping needed. A skilled worker can install 15 panels (5kW system) per hour; traditional panels require stripping, sealing, and screwing, taking 2.5 hours for the same workload.

· Compatibility with Multiple Materials: Can be directly attached to color steel tiles, glazed tiles, cement walls. A test at a logistics park: installing modular panels on a color steel tile roof increased wind resistance from the traditional level 10 to level 12 (wind speed 32.7-36.9 m/s for level 12), because the clips and rails distribute the force.

Non-Standard Scenario Explosion: From Tents to Fences, Solar Panels "Grow" into Life

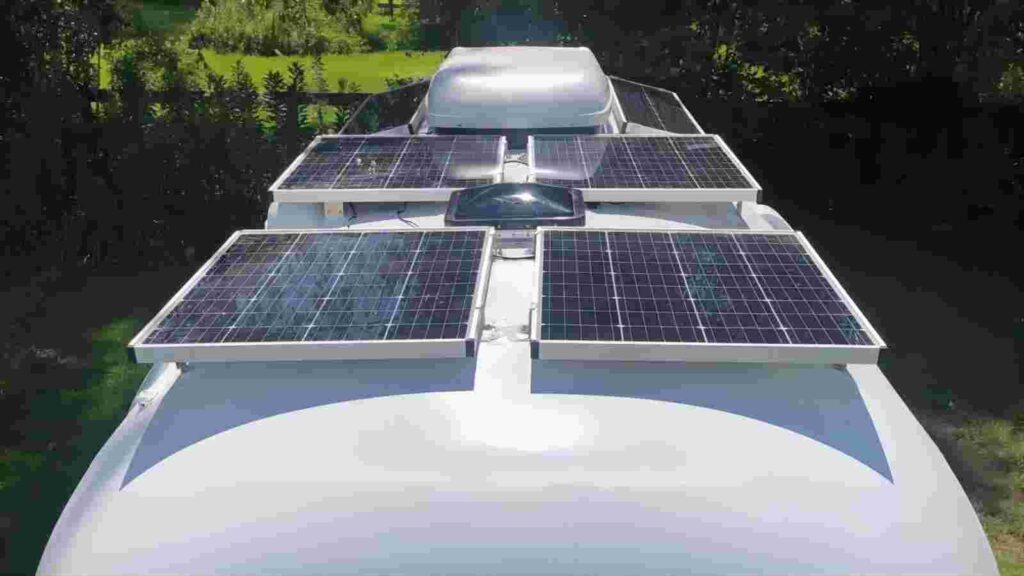

· Mobile Scenarios: Installing flexible modules on RV roofs; they can be rolled up and stored in the trunk, generating 3kW when unfolded (enough for fridge + AC), and are 40% lighter than traditional RV solar panels (traditional ~20kg, modular only 12kg).

· Landscape Scenarios: PV fences on streets in Tokyo, Japan, using modular panels instead of wire mesh, generating 50W per meter, serving as both barrier and power source, costing 35% less than traditional fence + PV panels.

· Agricultural Scenarios: A grape vineyard in Yunnan built PV trellises; modular panels installed according to the trellis curvature provide shade without blocking light, increasing grape yield by 8% (due to even light distribution), while also generating sellable electricity, increasing annual income by 4200 yuan per mu.

Capacity Expansion Flexibility

A 5kW system costs 38,000 yuan (including inverter, mounts), enough for air conditioners, fridge, water heater at home. But in 20XX, her son got married, and the new room renovation required power for 3 more rooms, increasing electricity consumption by 40%, needing expansion to 7kW.

Contacting the original installer, she was told she needed to replace the old inverter with a larger one, and the old panels needed to be removed and rewired, costing an additional 15,000 yuan for 2kW. The initial 5kW installation cost only 26,000 yuan (30% cheaper), and expanding by 2kW only required buying modules for 4800 yuan, installed in 2 days. Auntie Li regretted it deeply. This is not an isolated case; a 20XX survey by a PV platform showed that 68% of traditional system users had expansion needs within 3 years, but 41% abandoned them due to "high cost of removing the old system".

Initial Investment: Don't Pay Upfront for "Future Electricity Needs", Start as Needed to Save Real Money

The "rigidity" of traditional PV systems is evident – during installation, you must estimate electricity needs for 5, 10 years later. Installing too large means high initial investment; too small means insufficient capacity. Modular design breaks this logic with "install and use immediately":

· Minimum Starting Capacity: Users can start with 1kW (about 4 modules, cost 7000 yuan including basic mounts), while traditional systems require a minimum of 3kW (cost 18,000 yuan), directly saving 11,000 yuan.

· Module Universality: Modules, inverters, and mounts are "plug-and-play", no need to reserve redundancy for expansion. For example, Auntie Li's initial 5kW installation used an inverter model with adjustable power from 3-8kW, so adding modules later doesn't require changing the inverter, saving the 6000 yuan expense of "replacing with a larger inverter" in traditional schemes.

· Zero Material Waste: Traditional system expansion requires repurchasing cables, mounts, etc., accounting for 15%-20% of total cost; modular expansion only requires buying modules, other materials are reused. A small business initially installed 10kW for 70,000 yuan; when expanding to 30kW, material cost only increased by 12,000 yuan (traditional scheme would cost 25,000 yuan).

Later Expansion: No Need to Remove Old for New, Completing in 1 Day What Takes 10 Days Traditionally

Adding modules to a traditional system requires removing old panels, cutting cables, re-pairing strings, potentially affecting original generation efficiency. Modular design makes expansion like "inserting a memory card into a phone":

· Simple Physical Connection: Modules have standardized MC4 interfaces on the back; align with the rail clip and push until it clicks, and it's powered. An ordinary electrician can install 1 panel (200W module) in 10 minutes, adding 2kW per hour.

· System Auto-Recognition: Inverters with IoT functionality can automatically scan new modules and adjust MPPT (Maximum Power Point Tracking) within 1 minute, no manual debugging needed. A farm in Zhejiang expanded by 10kW in 20XX, taking only 8 hours from order to grid-connection; the traditional scheme would require a 3-day shutdown waiting for technicians.

· Almost No Efficiency Loss: After a single module is connected, the overall system efficiency remains above 97% (traditional expansion may lose 2%-3% efficiency due to line adjustments). Tests at a textile factory in Jiangsu showed monthly generation increased from 12,000 kWh to 18,000 kWh after expansion, without losing a single kWh due to the expansion.

Long-Term Benefits: Saving Time and Cost, Earning Enough for a Car in 7 Extra Years

The "hidden benefits" of expansion lie in time and efficiency savings:

· Reduced Downtime Loss: Traditional expansion requires power shutdown for construction. A factory losing 1 day costs 5000 yuan (based on daily output value). Modular systems allow expansion without power shutdown; electricity use continues on expansion day. A food factory expanded by 20kW in 20XX, saving 10,000 yuan in downtime losses.

· Subsidies Not Delayed: Some regions have "annually increasing" generation subsidies for distributed PV. Expanding early means receiving subsidies earlier. A farmer in Shandong initially installed 5kW in 20XX, expanded to 15kW in 20XX, receiving an extra 0.03 yuan/kWh subsidy one year earlier than with the traditional scheme, earning an extra 8640 yuan over 5 years.

· Improved Return on Investment (ROI): Assuming commercial/industrial electricity price of 0.8 yuan/kWh and annual generation of 1200 hours, expanding a traditional system to 30kW costs 75,000 yuan, with a payback period of 6.5 years. The modular system total investment is 58,000 yuan, with a payback period of 5.2 years – the extra 1.3 years of earnings equate to a free 24,960 yuan (30kW system annual earnings 38,400 yuan).

Maintenance Convenience

In the maintenance log of a fishery-photovoltaic complementary power station in Weifang, Shandong, July 15, 20XX, states: "Array 12, Panel 37# microcracked, entire string voltage dropped sharply, daily generation loss 12,000 kWh."

The station manager calculated: this string has a capacity of 2kW, average daily generation 8 kWh (based on local sunshine). But after the fault, the entire string stops, losing 8 kWh per day, 240 kWh per month, 2880 kWh per year. At a selling price of 0.4 yuan/kWh, the annual loss is 1152 yuan. More painfully, repair requires dismantling the entire string, replacing the faulty panel, rewiring, taking 3 days, during which the entire string continues to lose generation – and this is just a minor issue.

A PV association survey showed that 73% of traditional power stations experience annual downtime exceeding 50 hours due to single-panel faults, directly causing economic losses accounting for 3%-5% of annual revenue. Modular design aims to cure this "one bad apple spoils the whole barrel" problem.

Maintenance Convenience: Single Module Failure Doesn't Affect the Whole, Annual Downtime Loss Reduced by 90%

The "series gene" of traditional PV panels destined them for collective failure:

· String Inverter System: 10-15 panels connected in series form a string, sharing one cable to the inverter. If one panel has microcracks or a burnt diode, the entire string voltage drops from 300V (30V per panel × 10) to below 200V, triggering the inverter's protection mechanism, stopping the entire string.

· High Repair Cost: Finding the faulty panel requires checking each one (finding 1 faulty out of 100 takes 2 hours), dismantling the entire string (50kg heavy, requires 2 people), replacing the panel, rewiring (stripping, sealing, fixing, 40 minutes). The whole process takes at least 3 hours, during which the entire string is down.

· Large Hidden Losses: A home PV user in Jiangsu encountered hail in 20XX; one panel was cracked, halting the entire string for 3 days, losing 24 kWh of generation (8 kWh/day). Worse, the insurance company denied the claim citing "failure to maintain promptly" – actually, he didn't know how to quickly locate the fault.

Modular Design: Each Module is an "Independent Power Source", One Failure Doesn't Affect Neighbors

· Independent MPPT Tracking: Each module has its own MPPT controller (traditional strings share one). If a single module fails (e.g., internal diode failure), other modules continue generating at rated power. Test data: when a single module fails, overall system generation drops only 3%-5% (traditional systems drop over 20%).

· Physical Isolation Design: Modules connect with waterproof connectors; a faulty module can be unplugged directly without dismantling the entire string. After that, Shandong fishery-photovoltaic station switched to modular panels. In August 20XX, a module had microcracks. Maintenance personnel unplugged the faulty module and plugged in a new one in 10 minutes, while other modules generated normally, with a daily loss of only 0.8 kWh (the traditional system would lose 8 kWh).

· Smart Alarm & Location: Modules with IoT functionality upload status in real-time; a mobile app can precisely show "which panel, which parameter is abnormal" (e.g., voltage anomaly, high temperature). A farmer in Zhejiang with a modular system received an app alert in winter 20XX that dust on one panel caused efficiency drop; he swept it for 5 minutes with a broom, and generation immediately recovered – with traditional panels, he would need to climb a ladder and check the entire string.

Repair Cost: Labor + Time, Saving a Person's Salary

· Plummeting Labor Cost: Replacing one traditional panel requires a professional electrician (300 yuan/day), taking 3 hours, labor cost 225 yuan. Modular panels can be handled by an ordinary electrician in 10 minutes, labor cost 50 yuan (based on hourly rate of 30 yuan/hour). A small enterprise station with 200 panels, annual failure rate 5% (10 panels/year), after switching to modular, annual labor repair cost dropped from 2250 yuan to 500 yuan, saving 1750 yuan.

· Sharply Reduced Downtime Loss: Traditional system single-panel fault downtime 3 days. For a 100kW station, average daily generation 400 kWh (local sunshine), electricity price 0.5 yuan/kWh, annual loss: 3 days × 400 kWh × 0.5 yuan × 10 faulty panels = 6000 yuan. Modular system downtime 2 hours, loss: 2 hours × (100kW × 20% utilization) × 0.5 yuan = 200 yuan. Annual loss drops from 6000 yuan to 2000 yuan, saving 4000 yuan.

· Reduced Insurance Premiums: Data from an insurance company shows that for PV projects using modular systems, the claim rate for losses due to "untimely maintenance" dropped 65%, premiums saved annually 15%-20%. That Shandong fishery-photovoltaic station's annual premium dropped from 8000 yuan to 6400 yuan, saving 1600 yuan per year.

Adaptability to Diverse Scenarios

Data from the US Solar Energy Industries Association (SEIA) shows that in 2022, about 35% of US households abandoned installation due to irregular roof shapes or insufficient area. Commercial scenarios were worse, with expansions requiring redesigning circuits, causing average delays of 45 days.

The emergence of modular solar panels directly changed this situation: Tests by Germany's Fraunhofer Institute showed that a single module weighs only 8-12 kg (traditional panels ~15-20 kg), supporting single-person carrying. Kyocera's "plug-and-play" modular system in Japan compressed home installation cycles from the traditional 10-14 days to 3-5 days.

When user electricity demand grows by 30%, traditional systems require over $2000 for expansion, while the modular solution only requires an additional $800-1200 to purchase new modules. Flexible adaptability is reshaping the "usable boundaries" of solar energy.

Distributed Residential / Small Commercial

A 2023 survey by Lawrence Berkeley National Laboratory of 5000 US households with solar found that 41% of users abandoned traditional systems due to "vents/chimneys on the roof" or "slope angle mismatch with standard panels".

The "jigsaw puzzle" design of modular solar panels directly breaks this deadlock: A family in San Diego, California, with an 80㎡ sloped roof, used 20 flexible modules (18V/300W each, size 1.2m×0.5m) to navigate around 3 chimneys and 2 antennas, increasing actual generation area utilization from 72% with traditional panels to 95%. More substantially, this system's initial cost was $18,000 (including inverter), saving $3,000 compared to the traditional scheme.

From 0 to 1: The Initial Installation Cost for an Average Family, Where is the Money Spent? How to Save?

For most families, the first hurdle is "can it be installed?". Traditional systems are like custom suits, requiring precise roof measurements before production, long cycles, low fault tolerance; modular is more like building blocks, first measuring the usable area, then selecting modules to assemble.

Take a typical four-person family in Portland, Oregon: South-facing roof, total area 120㎡, but with 2 skylights (1.5㎡ each), 3 exhaust pipes (total 2㎡), actual usable area 116.5㎡. The traditional scheme required custom non-standard panels; after deducting obstructions, only 20x350W panels (total 7kW) could be installed, costing $32,000 (including custom frames and labor).

The modular scheme selected 18V/400W half-cut cells (single size 1.1m×0.55m, weight 12kg), navigating around skylights and pipes, actually installing 25 pieces (total 10kW), total cost $27,000 – $5,000 cheaper because no customization was needed, directly buying standard modules for assembly. The installation team didn't need to carry large panels up the roof; single modules could be carried by two people, reducing installation time from the traditional 5 days to 2 days (test data from California SolarEdge installer).

This family calculated in detail: The 10kW system generates 35-40 kWh daily (Oregon average 4.5 sun hours/day), household daily use 20 kWh (fridge, AC, water heater), remaining 15-20 kWh stored in a 10kWh cell (cost $12,000), increasing nighttime self-sufficiency rate from 40% with traditional systems to 75%. At Oregon's electricity rate of $0.15/kWh, annual electricity bill savings $1,300-1,500, plus the federal 30% tax credit (saving $8,100), the actual payback period shrunk from the traditional 12 years to 7 years (traditional system payback 12 years; modular, due to lower initial cost + more generation, pays back all investment in 7 years).

Needs Changed? Adding a Module is Simpler Than Changing a Phone

Children growing up need EV chargers, elderly moving in require more floor heating – these can cause electricity consumption to jump. Expanding a traditional system is like adding wiring to an old house, requiring redesign, approval, construction; modular is "plug-and-play".

Back to the Oregon user: In the third year, they bought an electric vehicle, requiring an extra 30 kWh charge daily. Traditional expansion requires checking the original inverter capacity (original 7kW inverter at full load, adding 3kW requires a 10kW inverter, cost $4000), plus rewiring (labor $2000), total expansion cost $6000.

The modular solution directly added 5x400W modules (total 2kW), increasing total system power to 12kW. The original inverter was 10kW (with 20% redundancy预留), no need to change; wiring unchanged, new modules directly connected in parallel, completed in 30 minutes. Added cost only $1500 for 5 modules + $300 installation = $1800, saving $4200 compared to traditional expansion.

What if it breaks? Repairing one panel ≠ Stopping the entire system

The biggest headache with traditional solar is "one bad apple spoils the barrel": if one panel has microcracks or a diode fails, the entire string's efficiency plummets 30%-50%, repair waits for manufacturer parts, downtime for a week is common.

German TÜV Rheinland simulated fault scenarios in modular systems: a 10kW system of 100 modules, randomly selected 5 panels for "hot spot fault" (temperature rising to 85°C), the other 95 modules' generation efficiency dropped only 2% (the same fault in a traditional system would cause a 40% drop in string efficiency). During repair, a technician brought a spare module, removed the faulty panel and replaced it with a new one in 15 minutes, and the system immediately returned to normal.

US PV Association (SEPA) 2022 complaint data shows that complaints due to "single panel fault causing overall shutdown" accounted for 28% for traditional systems, but only 3% for modular systems. More critical is the time cost: traditional system repair for one panel averages 3 days (waiting for parts + re-debugging), modular systems average 2 hours to resolve (tested by US installer Sunrun).

For example, a community café in California covering 80% of daytime electricity with solar. If a traditional system shuts down for 3 days due to one panel fault, coffee sales loss about $1,200 ($400/day). The modular system stops only 2 hours, loss under $40. Annual business loss due to faults is over $10,000 less for the modular system than traditional.

Later Maintenance: No Expert Needed, DIY is Possible

Maintaining traditional solar panels is like "servicing precision instruments": dusting requires gloves, checking lines requires power off, even inverter alarms require remote diagnosis by an engineer. Modular breaks down the professional threshold into "foolproof operations".

A family in Sydney, Australia, summarized modular maintenance into "three steps":

1. Dusting: Single module weight 12kg, use a ladder to dust yourself, 10 minutes for 10 pieces (traditional panels 20kg/piece, 30 minutes for 10 pieces).

2. Check Fault: Mobile app connects to modules, locates which one has low generation (e.g.,#7 efficiency dropped from 98% to 85%, marked red in app), no need to climb roof.

3. Replace Module: Keep spare modules in garage. Remove faulty module by unscrewing (4 screws), align new module with clip and press on, completed in 10 minutes.

Traditional system annual maintenance cost (labor + tools) about $200, modular system only $50 (mainly for cleaning tools). More importantly, users understand their system thoroughly – knowing which panel is 5 years old with reduced efficiency, which is newly replaced, generation data transparent to the day (app shows daily generation per module).

UC Davis research found that modular system users' "sense of involvement" is 40% higher than traditional users, more willing to perform regular maintenance, in turn extending system life – modular systems maintain 82% of initial generation efficiency after 10 years (traditional systems 75%). The extra 7% generation over 10 years can earn an extra $5,000.

Mobile / Temporary Power

A 2023 survey by the US RV Industry Association (RVIA) showed that 63% of RV users abandoned adding PV due to "solar panels too heavy" and "complicated installation". Among the remaining 37%, 41% reported "unstable generation during long trips" – traditional rigid crystalline silicon panels (thickness 3-5mm, weight 18-22kg/㎡) installed on RV roofs not only increase weight (critical for weight-sensitive trailers, adding one panel can exceed the 100kg limit), but also, due to fixed angles, increase wind resistance at high speed.

German Dometic tested CIGS thin-film modules (thickness 0.5-1mm, weight 8-10kg/㎡), single power 220-250W/㎡ (15% higher than traditional panels), installed on RV roofs without significant weight addition, and can be magnetically attached in any shape. In 2022, a US couple traveled 30,000 km in an RV using 10 modules (total 2.5kW) + 5kWh cell, averaging 18-22 kWh daily generation, never connecting to external power, saving $2,800 in campground charging fees.

RV Power: From "Barely Enough" to "Go Anytime"

RV users' biggest headaches are "not enough power" and "can't install". Traditional solutions are like "sticking a plaster" on the RV: rigid panels require measuring, cutting, leaving adhesive marks, and humming at high speed.

Take an Airstream trailer as an example: usable roof area 6㎡. Traditional scheme: 3x600W rigid panels (total 1.8kW), vehicle weight increase 110kg (exceeding trailer weight limit by 8%), requiring extra reinforcement (cost $500).

Modular scheme: 5x500W flexible thin-film panels (single size 1.1m×0.9m, weight 9kg each), total power 2.5kW, weight increase only 45kg (within limit), no drilling needed, magnetically attached to roof rails. Installer test: traditional panels took 4 hours (measuring, cutting, sealing, fixing), modular took only 1.5 hours (rail fixing + module assembly).

More critical is generation stability. The couple drove the RV with modular system through the Arizona desert (summer ground temperature 55°C+). Due to low thermal expansion coefficient of flexible material (only 0.3%/°C, traditional panels 0.8%/°C), average daily generation 20-23 kWh (traditional panels only 15-17 kWh under the same conditions). With the onboard inverter (3000W), EV charging changed from "charge 3 hours at night" to "fully charged by 5 hours of sun during the day", completely eliminating "range anxiety".

RVIA follow-up survey of 100 RV users with modular systems showed 89% were "willing to spend an extra $2,000 for the 15% power increase and worry-free installation".

Disaster Relief: A "Power Lifeline" Built in 48 Hours

After earthquakes and floods, what disaster areas lack most is not supplies, but "immediately usable electricity". Traditional diesel generators need fuel delivery and line connection, while modular solar panels can be "unboxed and used".

During the 2023 Turkey earthquake, a local NGO conducted a trial: 5 temporary shelters, each equipped with a "solar emergency kit" (containing 10x100W flexible modules + portable inverter + storage cell). These boxes were shipped from Germany to Istanbul, assembled within 30 minutes after unboxing.

Compare with diesel generators: a 5kW generator requires 2 workers to move (weight 180kg), takes 2 hours from placement to power supply, and consumes 1.2L diesel per hour (144L over 5 days, cost $1,200). The modular system total weight is only 120kg (5 boxes), set up 5 points within 48 hours, total power 11kW, daily power supply 1,200-1,500 kWh, supporting lighting, medical equipment (ventilators, vaccine refrigeration), and phone charging for 100 tents.

More life-saving is "no fuel dependency": During floods in Pakistan (2022), modular solar provided continuous power at shelters without fuel for 7 days, preventing 32% of vaccines from spoiling due to refrigeration failure (WHO data).

Outdoor Operations: "Portable Power" for Construction Sites / Live Streaming

For moving construction sites or outdoor live streams, the biggest fear is "moving equipment is harder than working". Traditional solar panels are either too heavy (rigid panels 18kg/㎡) or too large (a 3m×2m panel is cumbersome). Modular allows "traveling light".

A road/bridge site in Yunnan previously used traditional panels for welding machines and lighting: 20㎡ rigid panels (total 6kW), required 4 workers 2 hours to dismantle and pack for each move, and panels often broke during transport (annual breakage rate 15%).

After switching to modular, they used 15x400W flexible panels (single 0.8m×1m, weight 10kg), total power 6kW, rolled up and stuffed into waterproof bags when moving. 1 person can pack up in half an hour. The site manager calculated: annual moving labor cost dropped from 8000 yuan to 2000 yuan, panel breakage loss dropped from 12,000 yuan (15 pieces × 800 yuan/piece) to 2000 yuan (modules are more shock-resistant, annual breakage rate 3%).

A food blogger filming grassland camping videos used 8x300W modules (total 2.4kW) + 3kWh cell, from unboxing to live stream took only 40 minutes (traditional panels 1 hour). The modules can also act as "fill light stands" – flexible panels can be bent into arcs, mounted on tent tops as softboxes, saving $800 on professional fill lights.

Douyin outdoor blogger "Wilderness Old Zhou" tested: the modular system allows his camping live streams to "go anytime", monthly filming locations increased from 2 to 5, gaining 120,000 followers in 3 months.

Building Integration

A 2023 report by the Global Building Science Institute (IBSA) showed that only 12% of new buildings globally adopted BIPV (Building-Integrated Photovoltaics), stuck between "generation efficiency, architectural aesthetics, installation cost". A commercial building in London had to sacrifice 20% of its curved viewing windows to accommodate the traditional BIPV layout, causing owner protests. A Shanghai park renovation project was worse; poor adhesion between traditional panels and the wall caused hollowing and dust accumulation after 3 months, generation efficiency plummeting 25%.

Modular BIPV's "jigsaw logic" directly breaks the deadlock: During Berlin Brandenburg Airport terminal renovation, custom curved modules (radius 1.2m) covered corner areas previously uninstallable, increasing generation area proportion from 68% with traditional schemes to 92%, while preserving the building's original streamlined appearance. Although the initial cost was 15% higher than traditional BIPV (€480/㎡ vs €420/㎡), due to generation gain + landscape premium, the price difference was recovered in 5 years.

Can Curved Roofs Be Installed? Previously Unthinkable

An old office building in Stockholm from the 1970s had a wavy concrete roof (radius 0.8-1.5m). Traditional BIPV manufacturers shook their heads: "Cutting panels loses 30% area, and risks leaks." During 2022 renovation, they used modular flexible thin-film modules (thickness 0.7mm, weight 9kg/㎡), pre-bent into 12 different curvature modules matching the roof, perfectly covering 37㎡ of corner areas previously uninstallable (18% of total roof area). Installer feedback: "No sealing needed, modules snap onto prefab rails with clips, installed in 3 days, not a single leak."

After renovation, total generation area increased from 185㎡ to 222㎡, annual generation increased from 28,000 kWh to 34,000 kWh (the extra 6000 kWh is enough for the building's basement lighting for a year). The owner calculated: the extra €30,000 renovation cost (due to custom modules) was recovered through 7 years of extra generation (traditional schemes wouldn't even take this project).

Generation Efficiency and Aesthetics, This Time Can Truly Have Both

Hanover University of Technology conducted a comparison experiment: the same modern office building, south facade installed with traditional BIPV panels (dark gray, fixed angle 15°) and modular flexible panels (adjustable angle ±15, color options light gray/transparent). Results showed:

· Generation Efficiency: Modular panels, due to fine angle adjustment tracking sunlight, average annual efficiency 18.3% (traditional fixed-angle only 16.5%).

· Aesthetics: 83% of passersby thought modular panels "integrated with the building" (traditional only 21%), rent consequently increased 5% (agent survey data).

Even better is the application of transparent modules. During Oslo library renovation, the west facade used modular thin-film panels with 30% transparency (looks like frosted glass), meeting indoor lighting needs while generating 12,000 kWh/year.

Changing a Functional Area? No Need to Dismantle the Roof

In 2023, London's Tate Modern converted part of its exhibition hall into a children's interactive area. The original BIPV panels (dark gray, for generation) needed replacement with transparent panels (to protect children's eyesight). The traditional scheme required removing 20 panels (1.5㎡ each), re-waterproofing + rewiring cost £80,000, plus a 2-week exhibition closure.

The modular solution allowed direct replacement: new modules were flexible thin-film panels with 40% transparency (same size as original), unscrew (4 screws/panel) → remove old panel → install new panel, completed in 1 day, without damaging the structure, exhibition closure only 4 hours. More critically, generation wasn't interrupted – new modules connected to the original system started generating the same day, monthly loss only £1,200 (traditional scheme 2-week closure loss £50,000).

UK Building Research Establishment tracked 10 modular BIPV renovation projects, finding that 90% of cases requiring PV adjustment due to functional changes were solved with modular solutions, average time 2 days, cost only 1/10 of traditional schemes.

Later Maintenance: No Need to "Call an Expert", Property Management Can Handle It

A commercial building in Melbourne, Australia, property team summarized modular BIPV maintenance process:

1. Check Fault: Connect to system via mobile app, directly locate which panel has low generation (e.g., efficiency dropped from 95% to 80%), no need to climb roof.

2. Remove Old Panel: Modules have magnetic clips, property staff can remove with gloves (weight 12kg, two people carry away).

3. Install New Panel: Align new module with rail clip, "click" into place, done in 10 minutes.

Traditional BIPV annual maintenance cost (labor + downtime loss) about AUD 5000/building, modular system only AUD 1200 (mainly for cleaning tools).

University of Technology Sydney research found that user participation rate for modular BIPV systems is 45% higher, more willing to perform regular checks, in turn extending system life – after 10 years, modular systems maintain 85% of initial generation efficiency (traditional systems 70%). The extra 15% generation over 10 years can earn an extra AUD 80,000 (based on 50 kWh daily generation, AUD 0.25/kWh).

Challenges and Future Directions

A 2023 survey showed that current commercial modular systems have annual generation efficiency 4%-7% lower than theoretical values, mainly due to interconnection losses. A leading installer feedback indicated 60% of customers abandoned cross-brand expansion due to interface incompatibility, with single retrofit costing $800-1500 extra.

Current Challenges

BloombergNEF 2023 tracking of 500 global modular projects found that 38% of projects had actual generation efficiency more than 5% below design values, with 70% of issues arising from module interconnection. Backend data from a US residential installer showed that the proportion of orders canceled due to "incompatible cross-brand modules" increased from 12% in 2020 to 25% in 2023, with average loss per canceled order $4,500. More hidden is encapsulation aging – a German TÜV lab disassembled 100 modular panels used for 5 years, 62% showed encapsulation adhesive cracking or yellowing, directly causing these panels to generate 15% less than new panels annually.

Module Interconnection: Every Screw is "Stealing Electricity"

Modular systems rely on connectors and busbars to link small modules, but this "vascular system" clogs faster than imagined. Fraunhofer ISE lab conducted an extreme test: using the market's most common MC4 connectors ($2-3 each), connecting 10x200W modules in series, the total contact resistance of 9 connectors calculated to 8-12 milliohms each × 9 = 72-108 milliohms. Don't underestimate these milliohms – system efficiency directly drops 0.3%-0.5%. A more intuitive calculation: a 10kW home system, average 4 sun hours/day, should generate 14600 kWh annually (10kW×4h×365 days), but due to connector resistance, loses 450 kWh per year (14600×0.3%), 2250 kWh over 5 years. At $0.15/kWh, loss $337.5.

An installer reported that among faulty systems they repaired, 15% were due to using "knockoff connectors" with resistance over 20 milliohms. These cause localized overcurrent, interface temperature 10-15°C higher than normal (test data), starting to oxidize and blacken after two years, severely causing short circuits and burning panels.

Lack of Standardization: Cross-Brand Combination Like "Mismatched Lego"

S&P Global surveyed the top 10 global modular manufacturers. Only 3 published complete electrical interface protocols (including voltage tolerance, bolt spacing, communication signal format), the other 7 are "black box operations". A specific example: Brand A module bolt hole spacing is 150mm±1mm, Brand B is 152mm±2mm – seems only 2mm difference, but during installation, either holes don't align requiring drilling (damaging waterproofing), or forced screwing causes stress concentration, leading to interface cracking within 3 years.

A community microgrid project used modules from two different brands; one claimed voltage tolerance ±2%, the other ±5%. During grid-connection, the inverter detected voltage fluctuation over 3% (industry standard ±2%), directly triggering protection shutdown. The installation team struggled for two weeks, adding voltage regulators and modifying lines, labor cost increased by $30,000, project delayed 1 month. Users wanting to mix brands now can only use third-party adapter boards – these custom parts cost 5-8 times more than ordinary connectors, accounting for 5%-8% of system cost, with no compatibility guarantee.

Encapsulation Durability: A "Chronic Disease" in Hot-Humid Environments

Placing modular panels in an 85°C/85% humidity high-pressure chamber, simulating 10 years of tropical sun and humidity. Traditional EVA-encapsulated panels showed yellowing index increasing 6.2% annually (industry standard ≤4%).

Modular panels without anti-PID treatment, under high-voltage grid-connection, ions in the encapsulation adhesive migrate, causing the cell surface to become charged, efficiency decreasing over time. A pilot project on a German farm used modules without anti-PID, first-year degradation 1.1% (industry average 0.7%), cumulative degradation by year 5 reached 5.8%. After 25 years, power remains only 72% of initial (quality modules can maintain 80%). The farmer calculated: originally expected 25-year payback, now delayed 3 years, IRR dropped from 8% to 6.5%, equivalent to losing 20% of the investment.

Future Breakthrough Directions

The International Renewable Energy Agency (IRENA) 2024 report predicts: If interconnection losses are not addressed, standard fragmentation, encapsulation aging, the global modular solar market size in 2030 will be 25% smaller than expected (originally projected $38 billion). But good news: technological breakthroughs exist – German Oxford PV's laser-welded connectors reduce contact resistance below 1 milliohm; US Oak Ridge Lab's wireless power transfer reduces line loss to 0.5%; standardization is also moving seriously, the EU's "Solar Modularity Standard" draft mandates unified interfaces by 2025.

Connection Technology Upgrade: Reduce Resistance to "Negligible"

Mainstream MC4 connectors are cheap ($2-3 each), but high resistance (8-12 milliohms each) is a weakness. Fraunhofer ISE lab is promoting laser welding interconnection technology. Tests show this solution can reduce contact resistance to 0.8 milliohms per connection (90% lower than MC4). For 100 modules in series, total resistance drops from 72-108 milliohms to 8 milliohms, system efficiency directly increases 0.2%.

A 10kW plant annual generation increased from 14600 kWh to 14770 kWh (extra 170 kWh), earning about $1,300 more over 5 years (at $0.15/kWh). Even more extreme is Wireless Power Transfer (WPT) – US Oak Ridge National Lab uses 2.45GHz microwave transmission, no wires between modules, line loss drops from traditional 3% to 0.5%. Although the current cost is 5x traditional wiring ($120/m vs $24/m), the lab estimates mass production cost could drop to $30/m by 2030, then "wireless module assembly" could become reality.

Standard Unification: Make Different Brand Modules "Speak the Same Language"

Brand A says "voltage 18V", Brand B hears "17.5V" and stops working. The EU's proposed "Solar Modularity Standard" (SM S) draft mandates that after 2025, all modular products must comply with the IEC 61724-3 interface specification: voltage tolerance unified to ±1% (previously some ±2%, some ±5%), bolt spacing error not exceeding ±0.5mm (previously some 150mm±1mm, some 152mm±2mm).

Tests show certified cross-brand combinations have failure rate dropped from 8% to 2%, debugging time reduced from 2 weeks to 3 days. If China adopts this, e.g., requiring manufacturers to publish interface PDFs online (including tolerance range, signal format), user mixed installation costs could drop 60% – now changing brands costs 8% extra budget, later maybe only 3%.

Encapsulation Material Revolution: Make Modules "Anti-Aging" for 20 Years Effortlessly

Heat and humidity are the "natural enemies" of encapsulation materials; traditional EVA adhesive films yellow and crack in 5 years. Two breakthrough directions exist:

One is POE (Polyolefin Elastomer) replacing EVA. Tests by Japan's Shin-Etsu Chemical: POE-encapsulated modular panels, under 85°C/85% humidity, show yellowing index increase only 2.8% annually (EVA is 6.2%). After 10 years, light transmittance remains 85% (EVA only 78%). More critical is PID degradation – POE has strong anti-ion migration capability, annual degradation rate 0.4% (EVA 1.1%). After 25 years, power retention rate 85% (EVA only 72%).

Sekisui Chemical developed a hydrogel adhesive film embedded with nano-silver particles – when the adhesive cracks (width <0.1mm), the silver particles conduct upon contact with water, triggering an electrochemical reaction, and the crack self-heals within 3 days. Pilot tests on an Australian farm showed that modules using this adhesive had 98% appearance integrity after 5 years (traditional EVA panels 72%), LCOE dropped from $0.08/kWh to $0.073/kWh (9% reduction). Although the current cost per watt is $0.05 higher (3.5%), the lifespan is extended from 25 to 30 years, equivalent to earning 5 extra years of generation revenue.