Which Is More Efficient, Monocrystalline Silicon Or Polycrystalline Silicon

Monocrystalline silicon panels edge out polycrystalline, averaging 23% efficiency vs 20% due to their uniform single-crystal structure that minimizes electron loss. A 400W monocrystalline unit generates ~12% more daily power than a 400W polycrystalline peer, making it preferable for limited roof space.

Efficiency Comparison: Key Numbers

As of 2024, the gap between panel types has widened. Modern monocrystalline panels, especially those using PERC, HJT, or N-Type TOPCon technologies, now commonly achieve laboratory efficiencies between 22% and 24% for premium models, with some exceeding 25%. In contrast, standard polycrystalline panels have largely plateaued, with average efficiencies ranging from 15% to 17%. This 7 to 9 percentage point difference is significant in real-world applications.

Using monocrystalline panels rated at 22% efficiency (approximately 400 Watts each), you would need 15 panels. Each of these panels typically measures about 1.7 meters tall by 1 meter wide (around 1.7 square meters). The total roof space required would be roughly 25.5 square meters. Now, if you opted for polycrystalline panels with a 16% efficiency rating (producing about 300 Watts per panel), you would need 20 panels to achieve the same 6 kW system size. With a similar physical size per panel, the total roof space needed jumps to approximately 34 square meters. That's a 33% increase in the number of panels and a significant demand for more roof area, which can be a critical constraint for residential installations with limited space.

On a roof with ideal, unshaded conditions, the more efficient monocrystalline system will generate more kilowatt-hours (kWh) per square meter annually. For example, where the polycrystalline system might produce 900 kWh per square meter per year, the monocrystalline system could generate 1,050 kWh or more in the same location. Over the 25-year warranty period of the panels, this compounded difference in output can be substantial, affecting the long-term financial returns. Another critical, often-overlooked number is the temperature coefficient. Solar panels become slightly less efficient as they get hotter. Monocrystalline panels generally have a better temperature coefficient, around -0.30% per degree Celsius, compared to polycrystalline's typical -0.40% per degree Celsius. On a hot, sunny day when panel temperatures can be 35°C above the standard test condition of 25°C, the monocrystalline panel's output will only be reduced by about 10.5%, while the polycrystalline panel's output drops by approximately 14%.

Key Metric | Monocrystalline Silicon | Polycrystalline Silicon |

Average Module Efficiency (2024) | 22% - 24% (Premium: 24%+) | 15% - 17% |

Panels for a 6 kW System | 15 x 400W panels | 20 x 300W panels |

Estimated Roof Space Needed | ~25.5 sq meters | ~34 sq meters |

Typical Temperature Coefficient | -0.30% / °C | -0.40% / °C |

Power Loss at 35°C above STC | ~10.5% | ~14% |

Estimated Annual Degradation | 0.30% - 0.50% | 0.50% - 0.80% |

High-quality monocrystalline panels often come with a guarantee that their output will still be at least 92% of the original nameplate rating after 25 years, which equates to an average annual degradation of about 0.30% to 0.50%. Polycrystalline panels tend to degrade slightly faster, at about 0.50% to 0.80% per year. After 25 years, this difference means a monocrystalline panel could still be operating at 89-92% of its initial capacity, while a polycrystalline panel might be down to 82-87%.

Manufacturing Process and Cost

The fundamental difference in efficiency between monocrystalline and polycrystalline silicon panels boils down to the atomic-level structure of the silicon material itself, a direct result of the manufacturing process. This process is the primary driver behind the 20% to 30% higher initial cost per panel for monocrystalline technology compared to its polycrystalline counterpart. Creating a perfect, single crystal silicon structure is an energy-intensive and meticulous operation. It involves heating highly purified polysilicon to a melting point exceeding 1414°C inside a quartz crucible and then slowly drawing a seed crystal upward at a painstakingly slow rate of a few millimeters per hour.

The core cost difference lies in the initial crystal growth: monocrystalline requires a slow, energy-intensive process to create a single, perfect crystal, while polycrystalline allows silicon to cool in a mold, which is faster and cheaper but results in a less ordered structure with lower efficiency.

Instead of the slow drawing process, raw silicon is simply melted and poured into a large, square mold where it is allowed to cool and solidify over a period of 20 to 30 hours. This method, known as directional solidification, is far more scalable and consumes less energy per ingot. The primary advantage is the high material utilization; the resulting blocks are already square, minimizing the waste seen from squaring monocrystalline ingots. This efficiency in production is why, for many years, polycrystalline panels dominated the market as the more affordable option, sometimes costing 0.10to0.15 less per watt at the peak of its popularity.

Where wafer thicknesses were once consistently 200 microns, advanced manufacturing can now produce wafers as thin as 150 microns, increasing the number of wafers per ingot by over 15%. While both technologies benefit, the higher initial value of the monocrystalline ingot makes any reduction in kerf loss especially valuable from a cost perspective. This manufacturing improvement is a key reason why the price premium for mono panels has decreased from over 30% a decade ago to a more modest 10-20% today.

If a monocrystalline panel produces 50 more watts than a polycrystalline panel of the same physical size, the balance-of-system cost savings (racks, cables, labor) can partially offset the panel's higher price. Furthermore, the typically lower degradation rate of monocrystalline panels—around 0.3% per year versus 0.5% for polycrystalline—means that over a 25-year period, the mono system will generate more cumulative electricity.

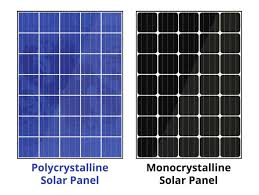

Appearance: A Visual Guide

While efficiency and cost are critical metrics, the visual appearance of solar panels is a major deciding factor for homeowners and architects. The aesthetic difference between monocrystalline and polycrystalline panels is immediately obvious and stems directly from their internal structure.Over the last 5 to 7 years, the demand for aesthetically pleasing solar installations has grown by an estimated 30% annually, making appearance a key differentiator beyond pure technical specifications. The choice often comes down to balancing upfront cost with the desired visual outcome for a property, which can also influence resale value.

The most striking difference is in color and texture. Monocrystalline panels have a signature look characterized by a pure, uniform black hue. This is achieved through several manufacturing techniques:

l Silicon Texture: The cells are made from a single crystal, which allows for a very even and dark color.

l Anti-Reflective Coating: Advanced coatings applied to the glass surface are optimized to minimize glare. These coatings increase light absorption, pushing efficiency above 22%, and simultaneously give the panel a deep, non-reflective black appearance even from an angle.

l Backsheet and Frame: Modern all-black monocrystalline panels often use a black backsheet and a black anodized aluminum frame, creating a seamless, monolithic look that blends well with dark roof tiles like asphalt shingles or slate.

In contrast, polycrystalline panels are known for their speckled blue color. This appearance is a direct result of the manufacturing process where multiple silicon crystals are fused together. The boundaries between these different crystals reflect light at varying angles, creating a distinctive shimmering effect. The color can range from a brighter royal blue to a deeper azure, but it lacks the uniform darkness of monocrystalline.

Techniques like using more wires (e.g., 9-busbar to 15-busbar designs) that are thinner, or employing busbarless (shingled) cell technology, reduce the grid-like pattern on the cell surface. This creates a smoother, more homogenous black surface. Polycrystalline panels, often positioned as a value option, more commonly feature the standard 3-busbar or 5-busbar layout, making the electrical grid more prominent against the blue background.

Visual Characteristic | Monocrystalline Panels | Polycrystalline Panels |

Primary Color | Uniform, deep black | Speckled blue (varying shades) |

Surface Reflectivity | Low glare, matte finish | Higher reflectivity, shimmering surface |

Typical Frame Color | Black (for all-black models) | Silver |

Cell Layout Visibility | Low (9+ busbars, shingled cells) | High (3 to 5 visible busbars) |

Visual Consistency | High uniformity across the entire panel | Noticeable graininess and variation |

Best Suited For | Dark-colored roofs, modern homes, aesthetic-focused installations | Roofs where visual blend is less critical, budget-conscious projects |

From a design perspective, the choice is clear. If achieving a streamlined, low-profile look that integrates seamlessly with a dark roof is a priority—for instance, on a custom home where architecture is key—the uniform black appearance of monocrystalline panels is overwhelmingly preferred. The panel array appears as a intentional, dark surface rather than a conspicuous addition. For installations where the highest possible energy output per square foot is needed and the roof space is limited, the higher efficiency of monocrystalline panels, often exceeding 22%, means fewer panels are needed to meet energy goals, resulting in a less cluttered roof appearance.

Performance in High Temperatures

A solar panel's performance in real-world conditions doesn't always match its laboratory rating, which is measured at a standard cell temperature of 25°C (77°F). On a sunny day, it's common for rooftop solar panels to operate at temperatures between 45°C and 65°C, which can be 20°C to 40°C above the standard test condition.

Key Metric | Monocrystalline Panels | Polycrystalline Panels |

Typical Temperature Coefficient (Pmax) | -0.30% to -0.35% / °C | -0.40% to -0.45% / °C |

Power Loss at 45°C (20°C above STC) | ~6.0% to 7.0% | ~8.0% to 9.0% |

Power Loss at 65°C (40°C above STC) | ~12.0% to 14.0% | ~16.0% to 18.0% |

Peak Power Output at 45°C (400W panel) | ~372W - 376W | ~364W - 368W |

Relative Performance in High Heat | Better performance retention | Reduced performance retention |

For every single degree Celsius that the solar cell temperature increases above 25°C, the panel's maximum power output decreases. A monocrystalline panel with a coefficient of -0.30%/°C will lose 0.30% of its power for each degree of temperature rise. In contrast, a polycrystalline panel with a coefficient of -0.42%/°C will lose 0.42%. This difference might seem small per degree, but it compounds dramatically under the sun. On a day when the panel's surface reaches 45°C (a 20°C increase), the monocrystalline panel's power output would be reduced by approximately 6.0%, while the polycrystalline panel's output drops by about 8.4%. For two panels both rated at 400 watts under ideal lab conditions, the real-world output at 45°C would be around 376 watts for the mono panel versus 366 watts for the poly panel. Over a 6-hour peak sun period, that's a difference of about 60 watt-hours of lost energy generation per panel, per day.

The reason for this performance gap lies in the semiconductor physics of the silicon material. The primary factors include:

l Crystal Structure Purity: The single, continuous crystal lattice in monocrystalline silicon offers less resistance to the flow of electrons (holes and electrons). This higher charge carrier mobility is less affected by the increased thermal vibrations that occur at high temperatures. The disordered grain boundaries in polycrystalline silicon act as obstacles, increasing resistance and exacerbating power loss as heat energy agitates the structure.

l Bandgap Properties: Silicon's inherent bandgap of approximately 1.1 electronvolts (eV) makes it sensitive to temperature. As temperature rises, the semiconductor's bandgap narrows slightly, which increases the number of electrons excited by heat rather than light. This creates a higher reverse saturation current, effectively lowering the voltage the cell can produce. The more efficient and pure monocrystalline cells typically have a slightly better voltage characteristic to begin with, which contributes to their superior temperature response.

l Advanced Cell Technology: Many modern monocrystalline panels incorporate technologies like PERC (Passivated Emitter and Rear Cell) or N-type silicon. These designs are particularly effective at reducing a key loss factor called carrier recombination. At high temperatures, recombination rates increase, but PERC and N-type technologies inherently suppress this effect. For example, an N-type mono panel might have a temperature coefficient as low as -0.26%/°C, compared to -0.41%/°C for a standard P-type poly panel.

In a region like Arizona or Spain, where average panel operating temperatures can be 10-15°C higher than in temperate climates, the total annual energy production gap between the two technologies widens beyond the nameplate efficiency difference. A system using monocrystalline panels might outperform a similarly rated polycrystalline system by an additional 2% to 4% annually solely due to better high-temperature performance. This makes the temperature coefficient a critical financial parameter, not just a technical one, as it directly increases the total kilowatt-hours delivered over the system's 25-year lifespan, improving the return on investment.

Lifespan and Durability Over Time

Both monocrystalline and polycrystalline panels are designed for exceptional longevity, with industry-standard product warranties of 25 to 30 years and an expected functional lifespan often exceeding 40 years.

The most significant factor influencing long-term durability is Light-Induced Degradation. This phenomenon occurs in the first few hundred hours of exposure to sunlight and is caused by oxygen impurities in the silicon interacting with the boron dopant used to create the P-type silicon common in both technologies. The crystal defects that form act as recombination centers, reducing the cell's efficiency. Monocrystalline panels typically experience an initial LID power loss of about 1% to 2%, which stabilizes after the first year. Polycrystalline panels, with their more disordered structure containing more grain boundaries and impurities, can suffer a higher initial LID, often in the range of 1.5% to 3%.

The average annual degradation for a premium P-type mono panel is typically 0.30% to 0.50%. For N-type mono panels, this rate can be as low as 0.20% to 0.30% per year. Polycrystalline panels, on the other hand, generally have a higher average annual degradation rate, usually falling between 0.50% and 0.80%. This difference is primarily due to the higher density of crystal boundaries in poly-Si, which are more susceptible to forming stable defects under continuous thermal cycling and UV exposure over time. Over a 25-year period, this means a high-quality monocrystalline panel is guaranteed by many manufacturers to still produce at least 92% of its original power output after the first year, and often 87-90% after 25 years. A polycrystalline panel's warranty often guarantees a lower end-of-life performance, typically around 82-87% of the original output.

A typical warranty might state that the panel will not degrade by more than 2% in the first year (accounting for LID), and then by no more than 0.45% or 0.55% per year thereafter. The cumulative effect on energy production is substantial. Over 30 years, a system with a 0.35%/year degradation rate will produce approximately 15% more total energy than a system degrading at 0.70%/year, assuming they start with the same initial output.

Choosing for Home or Business Use

The market has shifted decisively, with monocrystalline panels now representing over 90% of new residential installations due to their superior performance characteristics. However, polycrystalline panels can still be a relevant choice in certain scenarios where the lowest initial cost is the absolute priority.

A typical residential rooftop has a finite, often limited, area for solar panels. Monocrystalline's higher efficiency directly translates into needing fewer panels to achieve a specific energy goal. For instance, to power a home with an annual consumption of 10,000 kWh, you might need a 7.5 kW DC system. Using high-efficiency monocrystalline panels (e.g., 420W each), this requires about 18 panels, occupying approximately 30 square meters of roof space. Achieving the same output with standard polycrystalline panels (e.g., 330W each) would require 23 panels, needing about 38 square meters. If your available suitable roof space is less than 35 square meters, the choice is effectively made for you: only the monocrystalline system will fit.

Decision Factor | Recommended Choice & Key Data Points |

Limited Roof Space (< 35 sq. meters) | Monocrystalline. Higher wattage per panel (≥400W) maximizes energy production in confined areas. A 7.5 kW system requires ~18 panels vs. 23 panels for polycrystalline. |

Tight Initial Budget (Lowest $/Watt) | Polycrystalline. Can offer a 0.10to0.20 per watt savings on panel costs. Optimal for large, unshaded areas where space is not a constraint. |

Hot Climate (Average Summer > 30°C / 86°F) | Monocrystalline. Superior temperature coefficient (-0.30%/°C vs. -0.42%/°C) results in 2-4% higher annual energy production in high-heat conditions. |

Aesthetic & Visual Appeal | Monocrystalline. Uniform black cells with black frames provide a seamless, low-profile look that integrates better with most residential roofs. |

Large Commercial/Rooftop (Space Abundant) | Polycrystalline can be viable. For warehouses or large buildings with 10,000+ sq. meters of roof, the lower per-panel cost can yield a faster ROI, accepting the space penalty. |

Maximizing 25-Year Financial Return (LCOE) | Monocrystalline. Higher initial output, combined with slower degradation (~0.4%/year vs. ~0.7%/year), typically results in a lower Levelized Cost of Energy over the system's life. |

While polycrystalline panels may have a lower acquisition cost—perhaps 250 per panel versus 300 for an equivalent-wattage mono panel—the balance-of-system costs must be factored in. These include racks, cables, and installation labor, which are often calculated per unit or as a fixed cost for the project. A system requiring 20% more panels will incur 10-15% higher balance-of-system and labor costs. Therefore, the final installed cost per watt difference between the two technologies is often narrower than the panel-only price suggests, sometimes as little as 0.05to0.10 per watt. For a 7.5 kW system, that's a total price difference of 375 to 750, which can be offset by the higher energy production of the monocrystalline system in just a few years.

As previously detailed, monocrystalline panels have a better temperature coefficient, typically around -0.30% per °C versus -0.42% per °C for polycrystalline. In a hot climate like Arizona or Florida, where panel temperatures regularly operate 30°C (54°F) above the standard 25°C test condition, the monocrystalline panel's real-world output will be approximately 3.6% higher solely due to its superior heat tolerance. Over 25 years, this performance advantage, compounded with the lower degradation rate, can result in the monocrystalline system generating 10% to 15% more total electricity.