Where should the fuse be located in the solar panel circuit

Install solar fuses between panels and charge controllers or batteries, rated 1.25×max operating current (e.g., 15A for 12V systems), using fast-acting UL 248-14 types with 600V DC rating to guard against short circuits and reverse overcurrent, ensuring circuit protection.

Fuse at the Cell Connection

A short circuit in a cable connected to a 12V, 100Ah lithium cell can easily generate over 1000 amps of current in a fraction of a second. This surge generates intense heat, capable of melting copper wiring (which melts at around 1085°C or 1985°F) in under 10 seconds, creating a severe fire risk.

The primary job of the cell fuse isn't to protect the cell itself, but to protect the wiring running from the cell to all your other modules, like the solar charge controller and inverter. The National Electrical Code (NEC) and standards like ABYC for marine applications are very clear on this point: any conductor connected directly to a cell's positive terminal must be fused within 7 inches (approximately 18 cm) of the terminal connection.

Here’s the deal: the fuse's rating is determined by the wire it protects, not by the device it powers. For example, if you are running a 2000-watt inverter from a 12V cell system, the maximum continuous DC current draw could be around 170 amps (2000W / 12V = ~166A, plus inefficiencies). You would likely use a 2/0 AWG cable, which has a typical maximum ampacity of 175-195 amps. To safely protect this cable, you would select a fuse with a rating that does not exceed the cable's ampacity. A 175-amp or 200-amp fuse would be the correct choice. This ensures that if a fault causes the current to spike to, say, 500 amps, the fuse will blow in a fraction of a second, well before the 2/0 AWG cable overheats to a dangerous level.

For these high-current cell connections, you want a fuse designed to handle high DC voltages and interrupt massive fault currents quickly. Class T fuses are often recommended for lithium batteries because they have an extremely high interrupting rating (up to 20,000 amps), allowing them to safely extinguish the arc from a powerful short circuit.

Fuse Type | Common Amperage Range | Interrupting Rating (AIC) | Best Use Case | Key Consideration |

Class T | 1-800A | Very High (20kA) | Lithium batteries, high-power systems near cell. | Fast-acting, best protection for high-energy batteries. |

ANL | 35-750A | Moderate (6kA) | General purpose, inverter circuits, cost-effective. | Good for systems with lead-acid batteries. |

MRBF (Terminal Mount) | 30-300A | High (10kA) | Space-constrained installations, direct cell post mount. | Very convenient, saves space, excellent protection. |

A cheap, poorly made holder for a 100-amp circuit can have significant internal resistance, leading to voltage drop and heat buildup at the connections. You should periodically, perhaps every 6 months, check the connections at the fuse holder for any signs of corrosion or heat discoloration, which can indicate a loose connection. A voltage drop measurement under full load should be less than 0.3 volts across the fuse and holder.

Placement on the Positive Cable

The fundamental rule, as defined by the National Electrical Code (NEC), is that the fuse must be placed within 7 inches (17.8 cm) of the energy source—which, in this context, is almost always the cell's positive terminal. This isn't a suggestion; it's a safety mandate designed to protect the entire length of the positive cable. The reasoning is simple physics: if a short circuit occurs on the unprotected section of cable before the fuse, the full, unlimited current from the cell will flow through the fault. A 100Ah lithium cell can deliver a short-circuit current exceeding 2000 amps for several seconds, generating enough heat to bring copper wire (melting point ~1085°C) to a molten state in under 15 seconds, posing a direct fire hazard.

Installation Scenario | Wire Gauge (AWG) | Max Continuous Current (at 90°C) | Recommended Fuse (Amps) | Max Distance from Cell Terminal |

Small System (e.g., to DC Load Panel) | 10 AWG | 30A | 30A | 7 inches / 18 cm |

Medium System (e.g., to Solar Charge Controller) | 6 AWG | 75A | 70A | 7 inches / 18 cm |

Large System (e.g., to a 2000W Inverter) | 2/0 AWG | 195A | 200A | 7 inches / 18 cm |

For a cable run from your cell to a solar charge controller that's 10 feet (3 meters) away, the fuse must be located right at the cell terminal, not halfway down the cable or at the controller's end. If the fuse is placed at the charge controller, that entire 10-foot (3-meter) length of positive cable is unprotected. A rodent chewing through the cable sheath 2 feet (0.6 meters) from the cell would create a direct short with no fuse in the circuit to interrupt it. The resulting current surge would heat the cable to several hundred degrees Celsius almost instantly.

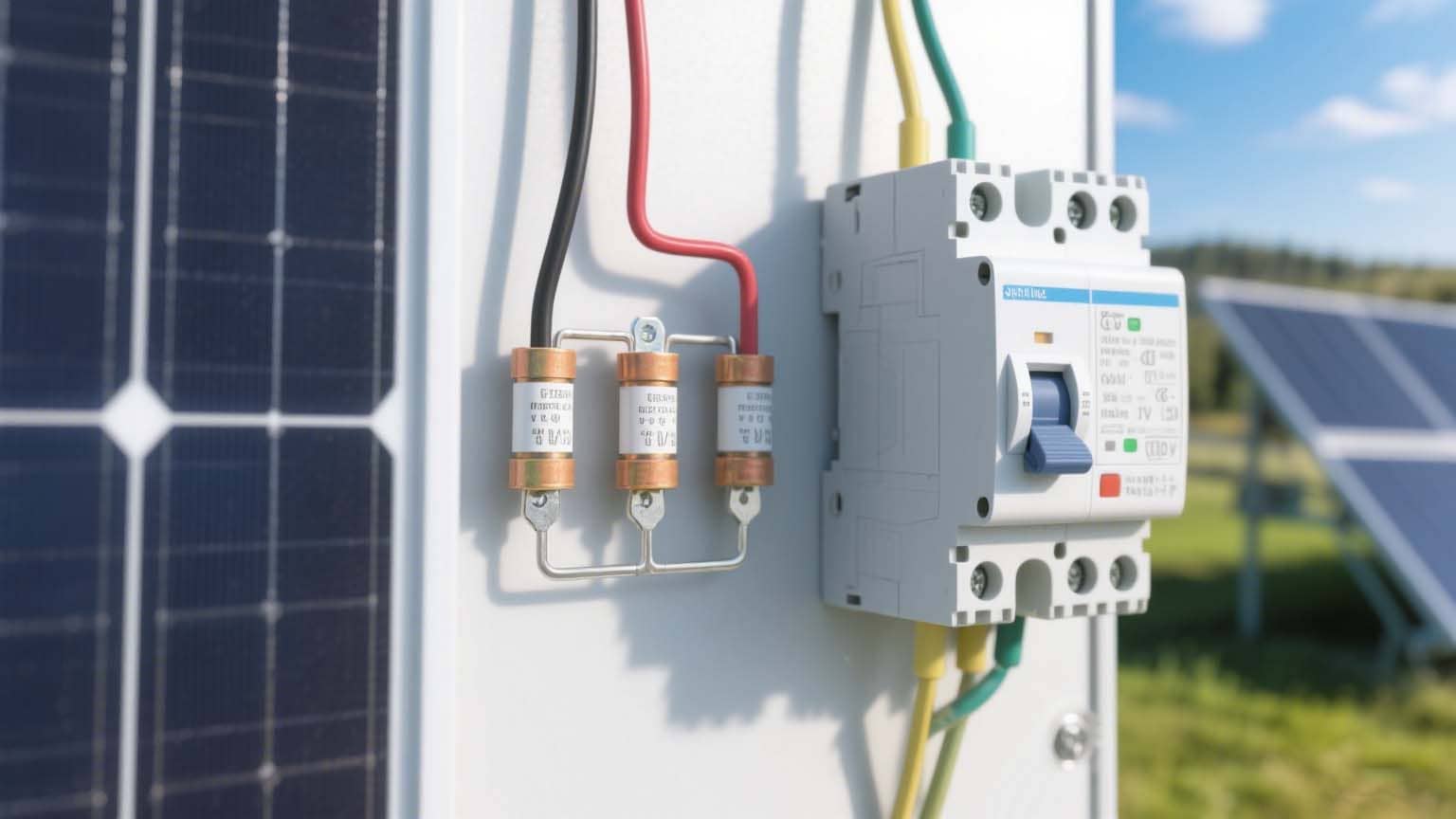

The correct method is to use a terminal-mounted fuse holder, like an MRBF type, which bolts directly onto the cell post. This setup ensures the cable is protected from its very origin. After the fuse, you can run the cable the full 10 feet (3 meters) to the charge controller, knowing it is safeguarded along its entire length. The distance between the cell and the fuse holder's connection point should be kept as short as physically possible, ideally under 4 inches (10 cm). Every centimeter of unprotected cable represents a potential failure point.

The principle of protecting the wire also dictates the fuse amperage. You must size the fuse based on the wire's ampacity, not the device's maximum draw. For instance, if your charge controller can output 50 amps, but you've used an 8 AWG cable rated for 55 amps, you should fuse the circuit at 50 amps or 55 amps. This protects the wire from being overloaded if the charge controller malfunctions and tries to pull more than its rated current. Voltage drop is another critical factor influenced by placement. While the fuse itself has minimal resistance (a good 100A ANL fuse might have around 0.0005 ohms), a poorly made connection at the fuse holder can introduce significant resistance. A loose connection with a resistance of just 0.01 ohms carrying 50 amps will generate 25 watts of heat (P = I²R = 50² * 0.01) and cause a 0.5-volt drop.

Protecting the Solar Charge Controller

The solar charge controller (SCC) is the brain of your solar power system, a sophisticated electronic device that can cost between 150 and 1000. It manages the energy flow from your solar panels, which can generate over 100 volts DC in open-circuit conditions, to your cell bank. Protecting this investment requires a dual-fuse strategy because it interfaces with two separate power sources: the high-voltage, variable-current input from the solar panels and the high-current, stable-voltage output to the cell.

A fault on either side can send destructive power surges through the controller's delicate internal circuitry, such as its maximum power point tracking (MPPT) algorithms and microprocessor. For example, a common 40-amp MPPT controller handling a 50-volt input from the panels and a 12-volt cell output is constantly managing a power differential that can exceed 500 watts.

The essential rule is to install two separate fuses: one on the positive cable between the cell and the controller, and another on the positive cable between the solar panel array and the controller. Each fuse is sized specifically for the cable and the maximum potential current on its respective side of the circuit.

The cable running from the cell to the SCC must be fused within 18 cm (7 inches) of the cell terminal. The fuse amperage here is determined by the wire gauge you've used. If you've installed a 40-amp controller using 6 AWG copper wire (rated for up to 75 amps at 90°C), you should use a 50-amp or 60-amp fuse. This provides a 25-50% overhead above the controller's maximum 40-amp output while ensuring the wire is protected. The primary threat on the cell side is a dead short inside the controller, which would cause the cell to dump its entire available current—thousands of amps—back through the controller, instantly destroying its output transistors.

A properly sized fuse will blow in under 0.1 seconds when faced with such a massive over current, acting as a sacrificial module that costs 10 to save a 400 controller. The second fuse is placed on the positive cable from the solar panels, close to the controller's input terminals. This fuse is sized based on the short-circuit current (Isc)of your solar array.

The National Electrical Code requires a fuse rated at 156% of this value for continuous loads, so you would select a 40-amp or 45-amp fuse (30A * 1.56 = 46.8A, rounded down to the nearest standard fuse size). This fuse protects the wiring from the panels in case of a fault between the array and the controller. It also provides a second layer of defense for the controller. If the controller's internal diodes fail, causing the cell voltage to backfeed into the solar panel circuit, this fuse will blow, isolating the fault. Ambient temperature significantly affects fuse performance; a fuse rated for 40 amps at 25°C (77°F) may only carry 35 amps safely in a 50°C (122°F) environment inside an enclosure.

Fuse for Multiple Panel Strings

A single 400-watt panel might have a short-circuit current (Isc) of 10 amps, but connecting three such strings in parallel creates a potential source of 30 amps. If one of those strings develops an internal short circuit, the combined power from the other two strings—now capable of pushing their full 20 amps backwards through the faulty string—can cause a dangerous reverse current flow. This current, unimpeded, will rapidly overheat the damaged string's wiring. The copper conductors within 10 AWG solar cable, rated for 30 amps, can reach temperatures exceeding 150°C within 60 to 90 seconds under a 20-amp overload, melting the insulation and creating a fire risk.

The National Electrical Code (NEC) specifically requires overcurrent protection for each parallel string when there are three or more strings. This rule exists because the aggregate current from the other strings can easily exceed the safe carrying capacity of a single string's wiring during a fault. Fusing each individual string is a critical safety measure to isolate a fault to a single branch, preventing a cascade failure that could take down the entire array and potentially damage the solar charge controller.

You must start with the panel's nameplate short-circuit current (Isc). For a panel with an Isc of 10.2 amps, you then apply the NEC's requirement for continuous loads, which mandates a multiplier of 156%. This gives you a minimum fuse rating of 15.9 amps (10.2 A * 1.56). Fuses are available in standard sizes, so you would round up to the next common size, which is a 15-amp fuse. It is crucial to note that the maximum size for this circuit is also governed by the ampacity of the wire used for the string. If you are using 12 AWG photovoltaic (PV) wire, which has a typical ampacity of 25 amps at 90°C, the 15-amp fuse is perfectly suited as it is both above the required minimum and below the wire's maximum safe capacity.

The fuse must be a DC-rated fuse, specifically designed for photovoltaic applications with a voltage rating exceeding your system's maximum open-circuit voltage (Voc). For a string with a Voc of 50 volts, a 15-amp, 150-volt DC fuse would be a standard choice.

When Combining Strings Together

A short circuit in one string would cause the remaining strings to backfeed their combined current. In a three-string array, two good strings could push 20 amps into the faulty one. In a four-string array, this jumps to 30 amps. This reverse current can quickly exceed the ampacity of the faulty string's 10 AWG wiring, which is only rated for 30 amps at 90°C, causing it to overheat to temperatures above 150°C in under two minutes, melting the insulation and creating a direct fire hazard.

l String Fusing: Each individual string's positive conductor runs through its own dedicated fuse holder. The fuse size is calculated as 1.56 x the string's Isc. For a string Isc of 10.2 amps, the minimum fuse size is 15.9 amps, rounded to a standard 15-amp DC fuse.

l Current Summation: The fused outputs of all strings are connected to a common positive busbar. The current on this main busbar is the sum of the currents from all operating strings.

l Main Cable Sizing: The cable exiting the combiner box to the charge controller must be sized for this cumulative current. For four strings with an Imp of 10 amps each, the maximum continuous current is 40 amps. Applying the NEC's 125% continuous load rule, the cable and main OCPD must be sized for at least 50 amps (40A x 1.25).

The following table illustrates the conductor and fuse sizing requirements for a system with four parallel strings, each with an Isc of 10.2 amps and an Imp of 9.8 amps.

Component | Parameter | Calculation | Resulting Specification |

Single String Wire (10 AWG) | Ampacity | 30A at 90°C | N/A |

Single String Fuse | Size | max(1.56 * Isc, ...) | 15A DC Fuse (10.2A * 1.56 = 15.9A) |

Combined Array Current | Total Imp | 4 strings * 9.8A | 39.2A |

Main OCPD & Wire Sizing | Minimum Ampacity | 39.2A * 1.25 | 49A → Use 50A Fuse/Breaker |

Main Output Wire (to SCC) | Conductor Size | 50A requires 6 AWG Cu | 6 AWG Copper Wire |

A box rated for outdoor use (NEMA 3R or 4X) with an IP65 or higher ingress protection rating is mandatory to keep out dust and moisture. The internal busbars should be made of tinned copper to resist corrosion over the system's 25-year lifespan.

Fuses and Power Optimizers

A system with 20 panels equipped with 300-watt optimizers can have a total combined output potential of 6,000 watts. The key safety feature is that most optimizers contain integrated electronics designed to limit their output current to a maximum of 1-2 amps above their nameplate rating during a fault, a critical difference from conventional panels.

The need for overcurrent protection is determined by the specific design of the optimizer and the system's configuration. The rules are not universal, so you must follow the manufacturer's installation guide precisely.

l String Fusing (Between Optimizers): In nearly all cases, you do not need fuses between individual optimizers within a single string. The optimizers' output current is electronically limited. For example, an optimizer with a maximum output current of 15 amps cannot force a destructive reverse current high enough to overload the wiring connected to its neighbors, which is typically 10-12 AWG cable rated for 30-55 amps. The fault current from one optimizer is simply insufficient to damage the parallel cabling.

l Main DC Fuse (Combiner Box): The primary point for fusing in an optimizer system is on the main trunk cable that combines the output of several parallel strings, just before it enters the inverter. This is because, while a single optimizer has a limited output, the combined output of many strings in parallel can generate very high currents. If a short circuit occurs on this main DC bus, the entire array—potentially dozens of optimizers—can feed current into the fault.

If you have 5 parallel strings, each with a maximum output current of 15 amps (as defined by the optimizer model), the total maximum available fault current on the main DC bus is 75 amps (5 strings × 15A). The cable running from the combiner box to the inverter must be sized to handle this current. Using the NEC's 156% rule for continuous loads, the cable and the main fuse must be rated for at least 117 amps (75A × 1.56).

A standard 125-amp DC fuse would be the appropriate choice. This fuse protects this main cable in the event of a short circuit between the combiner box and the inverter. The physical installation requires a DC combiner box rated for the system's maximum voltage, which can be 60V for some optimizer systems or 600V for others. The temperature inside this enclosure can consistently operate 20°C (36°F) above ambient, so a 125-amp fuse may need to be derated to an effective 110-amp capacity.