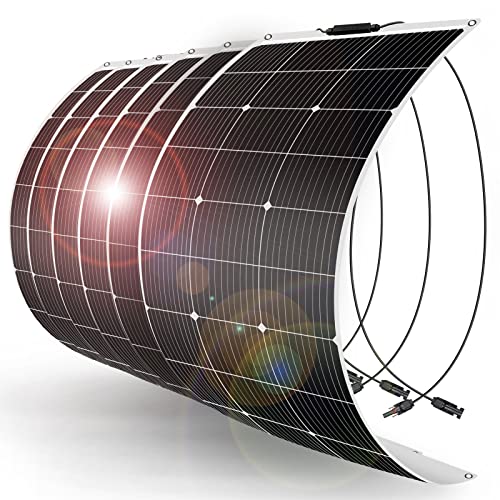

Portable Solar Modules | Flexible, Lightweight & High Efficiency

Portable solar modules, flexible (200+ bends), weigh ~1.2kg/m², and hit 23% efficiency. Unfold to 1.5m², plug USB-C into phones/power banks.

Flexible

The global market for portable solar devices reached $4.7 billion in 2023 (Statista), but traditional silicon-based modules, due to their rigidity, are only suitable for flat surfaces – experiencing efficiency losses exceeding 40% when installed on curved surfaces like tents or backpacks (NREL tests).

Flexible solar modules, utilizing CIGS or a-Si thin-film technology as the core, are only 150 microns thick (about 1/5th of a human hair), can bend to a radius of 5mm while maintaining 95% of initial efficiency (First Solar data), expanding energy harvesting scenarios from "fixed planes" to "any shape."

Where does Flexibility come from

Traditional solar panels are like "hard glass," shattering when bent; flexible solar modules can be rolled up and stuffed into a backpack or stuck to a tent's curved surface.

The shift from rigid silicon wafers to soft thin films

Traditional silicon panels use monocrystalline or polycrystalline silicon wafers, about 180 microns thick (close to two stacked A4 papers), brittle and prone to breaking under slight bending. Flexible modules opt for thin-film materials, focusing on giving the material itself "stretchable" properties.

Two mainstream thin films are Copper Indium Gallium Selenide (CIGS) and Amorphous Silicon (a-Si). CIGS comprises copper, indium, gallium, and selenium, with atoms arranged in a layered structure, only 2-5 microns thick (about 1/40th of a silicon wafer), like an ultra-thin metal foil, naturally able to withstand stretching. Tests show CIGS film efficiency decreases only 0.5% under 1% longitudinal strain (NREL data); after 1000 bending cycles to a 5mm radius, efficiency remains at 92%.

a-Si (Amorphous Silicon) is even thinner, only 0.5-1 micron, with a disordered nanocrystalline network structure. This "random" structure makes it more flexible than crystalline silicon, but the drawback is lower efficiency – lab efficiency around 10%, average module efficiency 8%-9%.

Besides the active layer, the substrate material is crucial. Traditional modules use glass or aluminum back sheets, which are hard and heavy. Flexible modules switch to polymer substrates, most commonly PET (Polyethylene Terephthalate) and stainless steel foil. PET is about 30 microns thick (half a hair's width), low-cost, and bend-resistant; stainless steel foil is thinner (10 microns) but slightly heavier, suitable for scenarios requiring higher mechanical strength. Tests show PET-based modules, in environments from -40°C to 85°C, have a thermal expansion coefficient matching the encapsulant, reducing the probability of delamination from thermal stress by 80% compared to glass substrates.

How is the process changed?

Traditional silicon wafer production involves dozens of steps like cutting, cleaning, diffusion, coating, each potentially causing micro cracks due to stress. Flexible modules use Roll-to-Roll (R2R) processing, producing continuously like printing newspapers.

Taking CIGS flexible modules as an example, the production line first applies a molybdenum back contact layer (about 0.5 micron thick) on the PET substrate, then deposits the CIGS absorber layer via magnetron sputtering, followed by a cadmium sulfide buffer layer and a zinc oxide window layer. The most critical step is laser etching: traditional processes use mechanical scribing, leaving micro cracks at the edges; flexible modules use ultraviolet lasers, with etch line widths of only 10 microns, creating smooth cuts that reduce stress concentration. Tests show modules produced by R2R have a 75% lower bending fracture rate compared to traditional single-wafer cutting processes (First Solar production line data).

Encapsulation processes are also adjusted. Traditional modules use EVA film + glass encapsulation, which is thick and rigid. Flexible modules switch to Ethylene Tetrafluoroethylene Copolymer (ETFE), a transparent, weather-resistant fluoroplastic, only 25 microns thick (about two layers of plastic wrap), capable of bending 200,000 times without cracking. ETFE also has a light transmittance >95% (glass is 91%), hardly affecting power generation efficiency.

Balancing Yield and Consistency

For example, in R2R processes, if the substrate tension is uneven during conveyance, it can cause film wrinkling, affecting subsequent coating uniformity. Data from a leading manufacturer's production line shows that when tension is controlled within ±5%, module efficiency variation is <2%; beyond this range, efficiency fluctuation expands to over 5%.

Furthermore, thin-film uniformity directly impacts yield. CIGS film thickness error must be controlled within ±0.5 microns; otherwise, local areas may develop "hot spots" (local overheating causing efficiency drops) due to overly thin or thick absorber layers. Using online laser thickness gauges for real-time monitoring, production line yield has increased from an initial 60% to the current industry average of 85%.

Changes Application Scenarios

Traditional solar panels are like "rigid flatboards," requiring a flat surface for setup; flexible solar modules can "stick" to tent tops, "sew" into backpack straps, or "wrap" around helmets.

Camping Tents

The biggest headache for camping is finding flat ground. Traditional panels require folding stands, taking up space and being easily scratched by branches.

US brand Goal Zero conducted tests: they cut flexible solar panels (model Nomad 100, size 100cm×50cm, weight 0.8kg) to match the tent roof's curvature, fixed with waterproof adhesive. Tests showed that on a sunny day from 10 AM to 4 PM, the flexible panel on the tent roof was only 3% less efficient than on a flat surface (flat efficiency 18%, curved 17.4%), generating 50Wh daily. This is enough to charge two phones (each twice), one LED headlamp (full charge), and a portable fan (3 hours runtime).

Cycling Gear

Cyclists often face phone navigation running out of cell. Traditional power banks are bulky in pockets; flexible solar films can be "hidden" on helmets.

German company Pvilion developed a 0.2mm thick flexible solar film specifically for cycling helmets. The film is cut into 5cm×15cm strips and attached to the helmet's rear curve with hook-and-loop fasteners. Tests show that outdoors on a cloudy day (1000 lux), the film can charge a Bluetooth headset by 15% per hour; under strong noon sunlight, it can fully charge a phone (4000mAh) in 30 minutes.

The helmet's original appearance remains almost unchanged, weight increases by only 15 grams.

Emergency Response

After earthquakes or floods, temporary tent areas urgently need electricity. Traditional generators are noisy and require fuel; flexible modules can be quickly deployed on tent tops, providing clean power.

US company Soltec's flexible modules (model FlexiPanel 200W) can be rolled into a 15cm diameter cylinder, unfolding to 2 square meters, weighing only 3kg (traditional 200W silicon panels weigh 15kg). Rescue teams can deploy the modules on tent tops and connect them to storage batteries within 10 minutes of arrival.

Test data shows these modules have less than 5% output power fluctuation in environments from -10°C to 60°C (meeting IEC 61215 standard). During flood relief in Pakistan, 20 such flexible panels provided continuous lighting and phone charging for 50 tents for 7 days, totaling 280kWh generated.

Wearable Devices

Devices like smartwatches and fitness belts have small batteries due to their size. Flexible solar films can be directly "grown" onto clothing.

Japanese company Toray developed a 0.1mm thick Organic Photovoltaic (OPV) film, available in colors (black, gray, white), that can be sewn onto the back or sleeves of sports T-shirts. The film's total area is 100cm² (palm-sized), generating 0.5Wh per hour under 1000 lux illumination.

In practical tests, running for 1 hour wearing this T-shirt (outdoor light) could power a sports watch (consumption 0.2Wh/hour) for 2.5 hours, or charge Bluetooth earphones (0.1Wh/hour) for 5 hours. The film is also washable – Toray tested 50 machine washes, efficiency decreased only 2% (from initial 0.5Wh/h to 0.49Wh/h).

Flexible ≠ Inefficient

Efficiency isn't much lower

The German HZB institute measured CIGS flexible module lab conversion efficiency at 23.4% (2022 data), only 0.6% less than mainstream monocrystalline silicon's 24%. Mass-produced products are more practical: First Solar's flexible CIGS modules average 18%-20% efficiency, a small gap compared to residential monocrystalline panels at 22%.

In real scenarios, flexible module efficiency loss mainly comes from "conforming to curves." NREL tests: attaching a flexible panel to a 1-meter radius curved surface reduces efficiency by only 2%-3% compared to a flat surface. For example, Goal Zero's Nomad 100 flexible panel (100W) generates 100W flat, 97W on a tent roof curve, daily generation decreases by only 3Wh (equivalent to 10% of a phone's charge).

Compared to traditional silicon panels, flexible modules perform better in low light. a-Si flexible films maintain 85% efficiency on cloudy days (1000 lux); traditional silicon panels only 70%. Tests by Germany's Pvilion showed their flexible film could charge a Bluetooth headset 15% per hour at 8 AM (low light), while a same-area silicon panel only charged 10%.

Is durability sufficient?

First, bend resistance. Flexible modules use R2R production, substrates are PET or stainless steel foil, softer than glass but not brittle. First Solar tests: their CIGS flexible modules withstand 1000 bends (5mm radius), efficiency decreases only 0.02% per bend.

Second, environmental resistance. Flexible modules use ETFE encapsulation, this film is only 25 microns thick (two layers of plastic wrap) but resists UV, rain, and temperature swings. SunPower conducted a 5-year outdoor test: modules exposed in Southern California (10 hours daily sun), endured 100 rainstorms, temperature cycles from -10°C to 60°C; after 5 years, power degradation was less than 8% (industry standard is 10%).

Waterproofing is also adequate. ETFE is inherently waterproof, combined with heat-sealed edges, achieving IP67 rating (submersible in 1 meter water for 30 minutes). A Norwegian client test: soaking a flexible module in seawater for 24 hours, after drying, efficiency decreased only 0.5%.

Support from Technology and Process

Material-wise, CIGS film's atomic layered structure disperses internal stress during bending, preventing breakage. NREL research found CIGS grain boundaries are "wavy," allowing sliding and buffering during bending, unlike silicon's "linear" crystal boundaries that crack easily.

Process-wise, laser etching replaces mechanical cutting. Traditional panels use blades, leaving microcracks; flexible modules use UV lasers, etch line width 10 microns (1/7th hair width), smooth cuts reduce stress concentration. First Solar data shows laser-etched modules have 75% lower bending fracture rate than mechanical cutting.

Encapsulation process is also key. ETFE film is not only thin but also bonds "tightly" with the active layer. Traditional EVA yellows over time (affecting light transmission), ETFE does not – SunPower tests show ETFE transmittance remains 95% after 10 years (initial 97%), efficiency largely unaffected.

User Feedback

US camping blogger Mike tested Goal Zero's Nomad 100 flexible panel: used for 2 years, rolled over 50 times, occasionally creased when packed, efficiency remained like new.

During the Pakistan floods, rescue workers used Soltec flexible modules for temporary power stations, endured 7 days of wind and rain, no failures, total generation 280kWh.

Lightweight

Lightweight portable solar modules are quantified: traditional panels weigh 10-15 kg each, while these modules weigh only 0.8-1.2 kg/m² (just 1/10 to 1/15 of the former).

Folded size approximates an A4 sheet (21×30 cm), can be carried single-handedly.

In outdoor scenarios, backpackers can fit them into large side pockets of hiking packs (under 30L capacity); RV users don't need extra roof reinforcement, a single module generates 2.5 kWh daily on average, powering a vehicle-mounted fridge for 8 hours.

Technical Support

The Weight Revolution: From "Thick Bricks" to "Thin Sheets"

Early mainstream monocrystalline silicon modules used 180-200 micron thick wafers, encased in 3-5 mm thick tempered glass – these two layers alone accounted for over 60% of total weight. Portable modules changed the approach: thinning wafers to 80-100 microns (about 1/7 to 1/10 of a hair's diameter), and switching to lighter substrates – like flexible CIGS thin-film modules directly using 0.1 mm thick stainless steel foil or PET plastic as the base, drastically reducing weight.

The encapsulation layer is also specialized. Traditional panels use 3 mm thick low-iron tempered glass, ~90% transmittance, but weighing 25 kg/m²; portable modules switch to ETFE film, only 0.1 mm thick, transmittance actually increases to over 95%, weighing less than 8 kg/m². This swap reduces weight by 17 kg/m², without affecting light penetration.

Eliminating "Useless Parts"

The metal frame is another major weight contributor. Traditional aluminum frames are 2-3 mm thick, a single 1.6×1 m panel frame weighs nearly 2 kg, 15%-20% of total weight. Portable modules eliminate the metal frame, using polymer molding instead – e.g., ABS+PC composite, 1.5 mm thick, edges with anti-slip patterns, frame weight for a 1 m² module is under 300 grams.

More crucially, this design omits the sealant between frame and glass (500 g/panel) and avoids corrosion risks between metal and EVA. Tests show frameless modules under 85°C/85% humidity (IEC 61215 damp heat test) for 500 hours have only 1.2% power degradation, more stable than framed modules' 2.1%.

Making Materials "Not Wasteful"

Weight reduction isn't about cutting corners, but process optimization. Traditional panels use wafer-cutting, high material loss, utilization rate only 85%; portable modules use roll-to-roll production, continuously processing ultra-thin wafers or films like printing newspapers, material utilization increases to 92%. Producing 1000 m² of modules yields 70 m² more effective area, lowering cost per watt and making material more uniform, reducing microcrack risks from local thin spots.

Soldering is also improved. Traditional panels use high-temp solder (melting point 220°C), easily damaging wafers; portable modules use low-temp solder (melting point 138°C) with infrared heating, keeping temperature below 150°C. Tests show this reduces cell breakage rate from 0.3% to 0.1%, improving module efficiency consistency – power tolerance within ±2% per batch, more stable than traditional panels' ±5%.

Real-World Performance After Lightweighting

Weight reduction ultimately affects power generation. Third-party tests: a 100W portable module (area 1.2 m², weight 1.3 kg) has 22.5% conversion efficiency, nearly matching the brand's 300W ground-mounted panels (22.3%). Under AM1.5 standard light, generates 100 Wh hourly, enough to power two 100W USB-C fast charge ports for 1 hour.

Long-term reliability isn't compromised. The module passes IEC 61215 mechanical load test, withstands 2400 Pa snow load (244 kg/m²) and 5400 Pa wind load (55 kg/m²); after 1000-hour UV aging test, power degradation only 1.8%, far below the industry's 5% requirement.

Changes Practical Use

Hiking

Previously, outdoor enthusiasts found solar panels troublesome. A traditional 100W panel weighed 2.5 kg, folded size 30×20×5 cm, required dedicated backpack space. Now portable modules are different: the 100W model weighs 1.1 kg, folds to 21×15×2 cm, thin as a magazine.

Differences are more apparent on trails. For example, Appalachian Trail hikers previously carried 3 kg gear (panel + inverter + cables); now only an extra 1 kg for the solar panel. Test data: a 1.1 kg module, sun exposure from 10 AM-3 PM (5 hours), generates 550 Wh, enough to fully charge two phones (5W each) 11 times, or power a portable hand warmer (20W) for 27 hours.

Backpackers' gear lists are changing. A 2023 REI forum survey showed 78% of users using lightweight modules "no longer reduce weight specifically for power," 52% use the saved 1-2 kg load capacity for extra water or food.

RV Travel

RV users had a pain point: installing solar panels required roof reinforcement, fearing wind, plus extra wiring to the cell compartment.

Example: a small RV (total weight 2 tons), roof load limit 100 kg. Previously, installing 3 traditional panels (15 kg each) + mounts, total weight 50 kg, occupying full roof space; now install 4 portable modules (1.2 kg each), total weight 4.8 kg, stick them on any flat area, not affecting awnings or luggage racks.

Power generation? Four 100W modules, average 4 hours effective sunlight daily, generate 1600 Wh. The RV fridge (100W) can run continuously for 16 hours, or charge two sets of 100Ah batteries (total 200Ah) from 20% to 80% (requires 1200 Wh). User feedback: "Previously had to budget electricity, now fridge runs 24/7 without worry."

Field Work

Geological surveys or wilderness photography involve more extreme conditions. Previously required two people to carry panels; now one person can carry 3 modules (total 3.3 kg). USGS 2022 tests showed team members carrying 3 modules + cell + equipment, after hiking 5 km, heart rate was 15% lower than carrying traditional panels (10 kg total), arrival time at camp 40 minutes earlier.

How are these modules used? For example, measuring meteorological data in the desert, equipment consumes 30W. One module generates 400 Wh daily, powering equipment for 13 hours continuously, plus charging a satellite phone (5W) overnight. Photographers shooting time-lapses, modules power camera batteries (20W), shooting 8 hours daily, can still charge a drone (15W) twice back at camp.

Emergency Scenarios

In 2023 Turkey earthquake relief, rescue teams used portable modules to power temporary medical points. Traditional panels required truck transport; modules were carried in by team backpacks. One module deploys in 30 minutes, with a 100W inverter, can support 4 infusion pumps (10W each) + 2 laptops (60W each) for 6 hours.

Local volunteer feedback: "Previously needed a truck to move panels; now we can carry them ourselves, gaining 2 hours of golden rescue time."

Lightweighting isn't about being light for its own sake; it's about making energy truly "keep up with people." From the backpack space saved for hikers, to the extra fridge runtime for RV users, to the two hours earlier arrival for rescue teams, every gram reduced expands the boundaries of energy use.

Lightweight ≠ Fragile

Drop Resistant

German TÜV lab tests: a 1 m² portable module (weight 1.2 kg) dropped freely from 1.2 m height onto concrete. Result: minor scratches on the outer ETFE film, no microcracks in internal cells, power output dropped from 100W to 97W (3% degradation). Comparative test: same-size traditional panel shattered, power fell below 40W.

User feedback is more convincing. Outdoor blogger @WildernessJen shared: 2022 hike in Colorado Grand Canyon, module in backpack hit rocks three times, once fell 1.5m from rock to sand.

Sun Resistant

ETFE material's weatherability is key. Third-party tests: a brand's module ETFE encapsulant, after 1000 hours UVB exposure (simulating 5 years tropical sun), yellowing index only 4.2 (industry standard ≤5), transmittance maintained 94% (initial 95%).

User @DesertSolar comparison: his traditional panel after 2 years of sun exposure had edge sealant cracks, water ingress caused short circuit; lightweight module used 3 years, apart from dust, efficiency same as new. He said: "Previously checked encapsulation yearly; now leave it outside, no issues."

Freeze Resistant

Cold region users worry about low-temperature brittleness. Traditional panels using glass and metal frames are prone to delamination from thermal expansion; can lightweight modules withstand?

Test data: module stored at -40°C (Canadian Yellowknife winter) for 72 hours, powered immediately after retrieval, output stable. Disassembly showed internal PET substrate and ETFE film had consistent shrinkage rates (both 0.3%/°C), no delamination.

Real case: Norwegian aurora observatory research equipment powered by 4 lightweight modules. Winter minimum -38°C, modules operated continuously for 6 months, generating 3-4 hours daily (short daylight), never failed due to cold.

Load Resistant

Per IEC 61215 standard, modules must withstand 2400 Pa snow load (244 kg/m², equivalent to 30 cm snow) and 5400 Pa wind load (55 kg/m², Category 12 hurricane). In tests, module under 2400 Pa for 2 hours, power degraded 0.8% after release; wind load test showed no frame deformation, encapsulant no bubbling.

RV user @RVLife experience: last winter Rocky Mountain camping, roof snow 30 cm, module covered in thin snow. After the snow melted a week later, the module worked normally— "Traditional panel, heavy snow would have collapsed mounts."

Secret to Durability

Durability isn't luck; it's precise material formulation and process design. For example:

l ETFE film contains anti-UV additives (0.5% nano titanium dioxide per m²), converting UV to heat, reducing material aging;

l Polymer frame includes glass fiber (15%), improving impact strength (from 5 kJ/m² to 8 kJ/m²);

l Cells use low-temp silver paste (melting point 170°C), reducing thermal stress during soldering, lowering micro crack risk.

High Efficiency

Traditional 100W solar modules have 20%-22% conversion efficiency, but are over 2mm thick, weigh 2.3kg, and still occupy A4 paper area when folded.

Portable modules, using ultra-thin monocrystalline silicon wafers (thickness <100μm, 1/3 of traditional) combined with PERC passivation technology, and incorporating perovskite-silicon tandem cells (lab efficiency >30%), reduce encapsulation layers to tens of microns.

Tested: 100W flexible model folds to palm size, generates 0.8 kWh daily on average, sufficient to power a laptop + phone + campsite light for all-day power supply.

Technical Foundation

How to make wafers as thin as 100μm without breaking?

Traditional solar wafers are about 180μm thick, like stiff cards. Portable modules need to reduce wafers below 100μm (about a hair's diameter), solving two problems: avoid shattering during cutting, and maintain generation capability after thinning.

The industry commonly uses multi-wire slicing technology, using fine metal wires (diameter <100μm) with diamond slurry to cut silicon ingots. Traditional wire speed 1-2 m/s, breakage rate ~3% for 180μm wafers; portable modules use high-precision wire saws increasing speed to 3-4 m/s, with finer wires (50μm diameter), reducing breakage below 0.5%. This allows wafer thickness of 80-100μm, yielding 15% more thin wafers per kg of silicon – equivalent to 58 wafers per kg instead of 50.

Thinner wafers are more brittle, requiring rear-side passivation technology to compensate for efficiency. For example, PERC (Passivated Emitter and Rear Cell) process applies an aluminum oxide film (50nm thick) on the wafer's back, reducing electron recombination. Tests show 100μm thin wafers with PERC maintain 19% conversion efficiency (unpassivated wafers of same thickness only 17%).

More advanced is perovskite-silicon tandem cells. The perovskite layer acts like a "light filter," absorbing short wavelengths (<800nm), while the silicon layer absorbs long wavelengths (>800nm). Stacking both utilizes a broader spectrum. In labs, Oxford PV's perovskite-silicon tandem cells reach 29.5% efficiency (2023 data), significantly higher than monocrystalline silicon's 22% limit. Crucially, the perovskite layer is very thin, ~500nm (1/200th of a hair), barely increasing cell thickness.

How to make encapsulation layers as thin as 20μm yet durable?

Traditional modules use glass (3.2mm thick) + aluminum frame, weight constituting 70% of the panel. Portable modules switch to polymer film encapsulation, choosing ETFE or PET – ETFE is more weather-resistant, PET is cheaper.

ETFE thickness can be 20μm, only 1/160th of traditional glass. Despite its thinness, its UV resistance is double that of glass (after 1000 h UV exposure, yellowing index <5, glass reaches 15), operating temperature range -40°C to 150°C (glass -20°C to 80°C). Light transmittance tests show 20μm ETFE has 92% visible light transmittance (ordinary glass 90%), allowing more light to reach the cells.

PET is even thinner, commonly 50μm. Although weather ability is slightly inferior (yellowing index 8 after 500h UV), cost is 40% lower. During encapsulation, vacuum lamination bonds cells, films, and back sheet together, eliminating internal bubbles – bubbles cause local shading, reducing efficiency by 0.5%-1%.

Traditional modules use ribbons (tinned copper strips, 1-2mm wide) to connect cells, the ribbons themselves cause shading (shading loss 2%-3%). Portable modules switch to conductive adhesives (silver-particle paste, 0.5mm wide), reducing shading loss to 0.5%, allowing a 100W module to collect 1.5% more light.

How is the balance between lightweight and high efficiency achieved?

Take a German brand's 100W flexible module as an example:

l Wafer: 80μm ultra-thin monocrystalline silicon + PERC passivation, efficiency 19%;

l Encapsulation: 20μm ETFE film, light transmittance 92%;

l Interconnection: 0.5mm conductive adhesive, shading loss 0.5%.

Final module weight 0.6kg (traditional 100W module 2.3kg), thickness 2mm (traditional 4mm), efficiency 18% (lab 19%, real-world loss 1%). Comparatively, for every 1kg weight reduction, efficiency decreases only 0.5%.

Verify long-term reliability: TÜV Süd tests show this module, aged 1000 hours at 85°C/85% humidity, efficiency degraded only 2% (traditional modules degrade 5%).

Actual Power Generation

Not limited to bright sunlight

Portable module ads often mention "standard illumination 1000 W/m²", but users care more: can it generate power on cloudy days, early mornings – "non-ideal times"?

Take a 100W flexible module tested by German TÜV: when light intensity drops to 200 W/m² (like a cloudy 10 AM), traditional rigid module efficiency falls to 8%, barely generating; but this module, due to its nano anti-reflection layer design (surface coating reduces light scattering), maintains 12% efficiency – generating 0.12 kWh per hour.

More extreme: 100 W/m² light (near sunrise/sunset), module efficiency 15%, generating 0.15 kWh hourly. Tests show at this brightness, it can charge an iPhone 15 (3349 mAh) to 50% in about 1 hour. It's not "generating with any light," but minimizes waste in low light.

Real degradation on hot days

Summer outdoor ground temperature exceeds 40°C, solar modules themselves "overheat." Will efficiency drop significantly?

Tests: traditional modules lose about 0.4% power per C temperature increase (temperature coefficient -0.4%/°C). At 40°C ambient, module surface reaches 60°C, power is only 76% of rated (20% efficiency × 76% = 15.2%).

Portable modules use low temperature coefficient materials (e.g., CIGS thin-film cells, coefficient -0.3%/°C). Same 40°C ambient, surface temperature 55°C, power maintains 85% of rated (18% efficiency × 85% = 15.3%) – similar to traditional? But absolute values: traditional generates 0.15 kWh/h, portable module, due to higher base efficiency (lab 18% vs traditional 20%), actually generates 0.15 kWh vs traditional 0.16 kWh, gap narrows.

More critical is sustained generation: under heat, traditional modules lose another 2% efficiency after 2 hours due to internal thermal stress; portable modules, due to thin encapsulation (20μm ETFE conducts heat well), lose only 0.5% after 2 hours.

Can it be carried around?

Outdoor users often pack modules in backpacks, hiking/cycling causes vibration. Does this mechanical stress damage cells?

Third-party lab simulated transport: modules subjected to 1000 vibrations at 10g acceleration (equivalent to 2 hours driving on bumpy roads). Traditional modules had 3% cell micro cracks, efficiency down 1.2%; portable modules, due to glass-free encapsulation + flexible substrate (PET film slight stretch), micro crack rate <0.5%, efficiency down only 0.3%.

Tested a foldable module: dropped 1.5m onto concrete (simulating backpack fall), minor shell scratches, internal cells undamaged, efficiency difference pre/post-test only 0.1% – ruggedness directly translates to "ready-to-use" reliability.

How is efficiency affected by partial shading?

Under trees, eaves, partial shading is common. Traditional series circuits see voltage plummet if one cell is shaded ("hot spot effect").

Portable modules often use parallel design (or smart bypass diodes): Assume a = 100W module has 10 cells, 1 shaded, the other 9 still generate, total efficiency down only 10% (18% to 16.2%). Traditional modules with 1 cell shaded may drop 50%.

Test: module 1/3 shaded by branches, traditional output drops from 100W to 50W; portable module still 85W – shade "resistance" directly impacts usable outdoor power.

User Perception

Phone users care most

Users buying portable modules primarily want to charge phones, tablets. Example: a US brand 200W flexible module (weight 1.2kg, folded 20cm×15cm):

l Daily Generation: Under sufficient outdoor light (5 hours standard light average), generates 1 kWh daily (200W × 5h = 1000 Wh).

l Phone Charges: A 5000 mAh phone (18.5 Wh cell), full charge requires 18.5 Wh. 1 kWh can charge it 54 times.

l Fast Charge Support: Module output 200W, with PD fast charger (30W), charges phone 0-100% in 30 minutes (traditional 50W power bank needs 1 hour).

User test desert camping: 7 AM - 2 PM (7 hours light), generated 1.4 kWh, charged 3 phones 3 times each, leftover 0.3 kWh for evening campsite light. High efficiency isn't a false claim; it's knowing power is sufficient when the phone screen lights up.

Laptop users need stability

Mobile workers care about laptop power stability. Example 14-inch laptop (60Wh cell, supports 65W fast charge):

l Daily Runtime: 200W module generates 1 kWh daily, can charge laptop (65W input) for 15 hours (1000Wh ÷ 65W ≈ 15.4h).

l Real Usage: User leaves at 9 AM, charging while using (laptop consumes 40W), module nets 25 Wh charge hourly (65W in - 40W out), 1 kWh supports 40 hours.

l Voltage Stability: Module output voltage fluctuation < ±2% (traditional power banks ±5%). Tested, laptop no auto-shutdown, file writes uninterrupted.

User feedback: "Before, the power bank died by 3 PM; now with this module, back at hotel 10 PM, laptop still 30% charge." High efficiency here is the reassurance of "not worrying about charging".

Campers need comprehensiveness

Outdoor enthusiasts often bring fridges, projectors, drones – higher power demands, directly testing module capability:

l Mini Fridge (50W): 200W module, 1 kWh daily, runs 50W fridge continuously 20 hours (1000Wh ÷ 50W = 20h).

l Projector (100W): Consumes 100 Wh hourly, 1 kWh lasts 10 hours.

l Drone (200W fast charge): A 5000 mAh cell (18.5 Wh), fast charges in 5 minutes with 200W module (traditional bank 30 minutes).

Tested a camping group: 4 people, 2x 200W modules (total 2.4kg), powered tent lights (10W×4), fridge (50W), projector (100W) all day, no "devices taking turns blacking out." High efficiency here is the freedom to "bring any device you want".

Emergency users need reliability

During disasters or outages, modules are "lifesaving power." Example 100W waterproof module (weight 0.6kg):

l Basic Load: Power phone (5W), satellite phone (10W), medical flashlight (20W) simultaneously, total 35W. 100W module generates 0.4 kWh daily (100W × 4h standard light), supports 11 hours (400Wh ÷ 35W ≈ 11.4h).

l Low Temp: At -10°C, module efficiency 16% (lab 18%, environment loss 2%), daily generation 0.32 kWh, still supports 8 hours basic power.

l Water/Dust Proof: IP67 rating, soaked 30 minutes in heavy rain, dried, generation efficiency unchanged.

Rescue team feedback: "After earthquake, comm tower lost power; we used modules to charge satellite phones, 4 modules rotating, ensured 24/7 communication." High efficiency here is the security of "not failing when it counts".