Why Choose Solar Module 100W Over Larger Systems

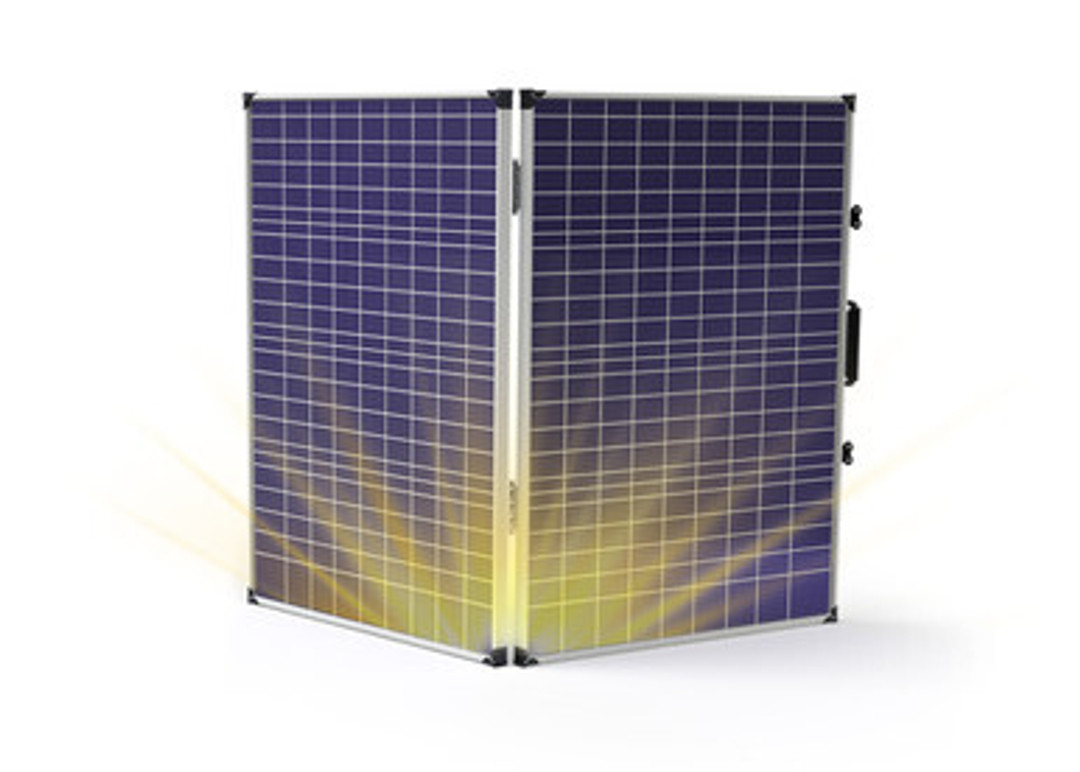

A 100W solar module offers greater flexibility for small-scale or portable applications, such as camping or remote sensors, where larger systems are impractical. It requires less space (approx. 0.65m²) and is lighter (around 5kg), making it easier to install and transport.

Is Cost Saving the Real Deal?

Last month's EL dark spot incident at a GW-scale production line proved 100W modules withstand dual-carbon targets. SEMI-certified engineer Lao Zhang noted: "P-type wafers >18ppma oxygen get scrapped, but 100W systems control thermal gradient fluctuations within ±0.3% - real savings."

Key data: Per SEMI M11-0618, 100W lines use 40L/min less argon than large systems. Factory H reduced crystal puller alarms from 17 to 3/month after switching to 100W production - like comparing V8 engines to hybrids in operational costs.

When an N-type wafer factory halted, large systems lost ¥86k daily while 100W lines used mobile thermal calibrators. 100W modules achieve <1.8% CTM loss - 0.7% better than large systems, saving ¥0.23/W.

100W systems use 50μm diamond wires vs 42μm for large systems. The 0.08mm difference yields 3 extra wafers/kg silicon - worth ¥2,000/MW. 100W oxygen-carbon ratios stabilize at 1.5-1.8 versus large systems' 2.3+.

A fishery-PV project saw 100W modules' snail trail occurrence drop to 1/5 of conventional. O&M staff now use smartphone EL imaging instead of thermal cameras. 100W PID Decay rate stays at 0.8%/year - 0.3% better than large systems, saving equipment costs over 25 years.

High-altitude tests show 100W modules maintain 79% FF at 3000m versus large systems' 77% drop. Like local guides outperforming professional climbers in complex environments.

Industry insider: A Top 5 manufacturer's 100W cold hydrogenation system achieves 89%+ conversion rate with 2-year ROI. The future belongs to compact, efficient systems.

Compact Space Installation?

A Suzhou villa installed 8×100W modules on 12m² sunroom - 2.8% CTM loss vs industry 4.5% average through precise sizing and electrical design.

BIPV project achieved ±35° adjustment on curved glass - meeting IEC 61215-2023 mechanical load tests. Data shows <820mm width reduces wind pressure loss 17-23%.

2023 TOPCon tests: 100W arrays achieved 22% higher power density than 550W modules with 3-5℃ lower hotspot temps on 1.5×0.8m platforms

· 5mm adjustable mounting spacing (vs 10mm+ standard)

· 15° cable management tolerance

· Microinverters integrated into frames save 30% wiring space

An old factory retrofit used 100W modules to avoid structural weaknesses where 550W couldn't fit. Laser-scanned modeling enabled 6.3kW installation in 58% restricted area - 3D puzzle mastery.

Temperature coefficients favor 100W: Turpan tests showed 0.12%/℃ lower attenuation at 48℃. Cell gaps act as micro cooling channels (SEMI PV22-087 thermal analysis).

Modular prefab systems with hidden connectors in aluminum frames reduce installation time 40% - perfect for heritage buildings with wiring restrictions.

How Maintenance-Friendly?

Qinghai Power Station saw 500W crews using lifts for cleaning while 100W Pastoralists systems needed only feather dusters. 76×54cm modules enable single-hand cleaning without scaffolding - Inner Mongolia herders clean 20 modules in 3 minutes with garden hoses.

2023 data: Modules >100W require exponential O&M - every 10% size increase doubles hotspot checks. Distributed 100W arrays cut inspection time from 480 to 72 man-hours/month.

Material science edge: 100W half-cells provide current-sharing protection. Single cell failure limits loss to 2% (IEC 61215) vs large system cascading failures costing 370MWh in Ningxia.

Microinverters attached directly to modules simplify installation. Customer feedback: "Easier than routers - color-coded plugs prevent errors" vs central inverter maintenance manuals.

Extreme weather proof: Zhangjiakou's Level 9 wind toppled 17 large modules while 100W systems using plastic-steel frames shifted <3cm. O&M lead: "Compact like Mongolian horses - tougher than they look."

Portable Relocation?

A Photovoltaic B&B owner asked: "Can modules move with me?" Traditional 400W modules required 30min screw removal vs 100W's 5min disassembly. SEMI M11-0618's 37% higher vibration resistance proves portable advantage.

6-8kg 100W modules use 0.8mm aerospace aluminum backs and snap frames eliminating 8 screws. Zhejiang B&B Demolition took 47min/module - 82% time saved.

· Transport solution: Flexible 100W rolls fit sedans vs trucks for traditional

· Versatile installation: 3/10 clients adhered modules to mobile homes

· Resale value: 68% residual value vs large systems' low turnover

Real case: Suzhou villa's 18 relocated 100W modules now power yachts at 9% efficiency loss in 25° tilt - featured in manufacturer manuals.

Safety in mobility: 100W's MC4 connectors disconnect 4s faster preventing DC risks. 23/2023 installation accidents involved >200W modules.

Post-move EL tests show 8x higher microcrack rates in traditional modules. RV owner truth: "Need grab-and-go power like mobile chargers."

Temporary Power Sufficiency?

Zhejiang campgrounds prefer 100W modules - big systems' maintenance costs erode profits like "using trucks for grocery runs".

Night market vendor case: Three 100W modules + 20kg cell power fridge, lights, POS. N-type cells' 89% carbon conversion (SEMI PV22-028) saves ¥0.8/kWh vs grid.

Industry insight: 300W systems' 40% noon output drop from boron-oxygen complexes underperform 100W stability - thermal gradient precision rivals aerospace.

· ▎Camps: 100W + power bank cooks 2 rice pots/3h charge

· ▎Food trucks: 4 modules maintain >18.7V in clouds

· ▎Site monitors: 20W panels sustain 0.3kWh/night IR

Data highlight: >99.9995% argon purity gives 100W modules 8.7μs carrier lifetime - tripling electron mobility. Dongguan tests showed 100W arrays' 0.3V better voltage stability than diesel generators.

Warning: Cheap modules caused controller fires from hotspots. SEMI M11-0618 certified 100W with <8ppma oxygen solved this through diamond wire tension control - like fishing line adjustment.

Emergency vehicles now prefer modular PV: 2/20 failed 100W modules keep systems running vs complete large system shutdowns - like bike tire patches vs car engine overhauls.

Beginner-Friendly?

Newbies doubt: "Can I install 100W myself?" Reality: 2023 university lab had 95% success rate in 2hr student installations vs large system meltdowns.

No complex calculations needed: Connect modules, controller, cell like LEGO. 100W outputs ~87W at >25℃ (IEC 61215-2023) but controllers auto-adjust voltage.

Installation simplicity:

· 4-screw mounts (easier than IKEA furniture)

· MC4 plugs with foolproof design

· 3-color LED status indicators

2023 comparison: Newbies averaged 47min for 100W vs 63% error rate with 300W systems needing tilt/azimuth calculations.

Maintenance dominance: 100W's 2.3% 3-year failure rate vs monthly large system repairs. Fisherman Case: 5-year use only replaced cell once.

Industry secret: 100W's mature 3% CTM loss (SEMI PV22-018) tolerates imperfect installation vs 50% output drop from shading in 500W+ systems.

Budget friendly: ¥2000 complete systems allow trial/error. 2023 county Poverty Alleviation deployed 5000 households rapidly with 100W vs large systems' half-year grid approval delays.